![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-61J

Model:

YS-61J

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

(L):30-170mm (W):30-130mm

Bag Size:

(L):30-170mm (W):30-130mm

![]() Film Material:

Packing material:BOPP/Polyethylene,Aluminium/PolvethylenePaper/Polvethyiene. Polvester/Aluminizer/Polvethvlene and so on

Film Material:

Packing material:BOPP/Polyethylene,Aluminium/PolvethylenePaper/Polvethyiene. Polvester/Aluminizer/Polvethvlene and so on

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

3-100ml(customizable)

Pack Weight Range:

3-100ml(customizable)

![]() Machine Size:

900*1100*1900mm

Machine Size:

900*1100*1900mm

![]() Machine Weight:

300kg

Machine Weight:

300kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

Bag Types:Our machines are widely used in the packaging of sauces, such as tomato sauce, chili sauce, salad sauce, and so on. Our models are complete and diverse for customers to choose from.

Film Material:Polypropylene/Polyethylene, Aluminum Foil/Polyethylene.

1.Touch ScreenPLC :

Intelligent control touch screen,Can adjust the temperature, packagesize and package weight

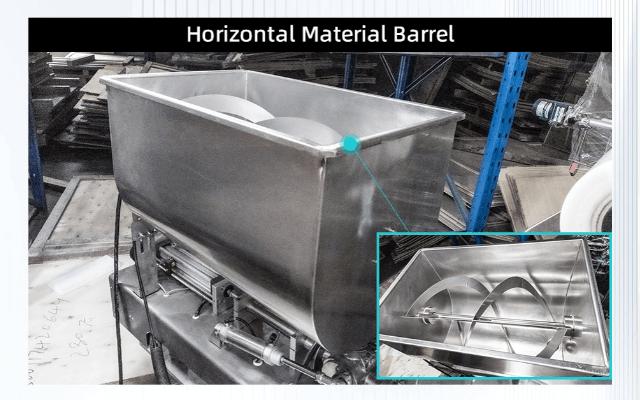

2.Horizontal Material Barrelcapacity:

RequlatorThe filling capacity can be adjusted by the turntable, with arange of approximately 3 to 100 gram

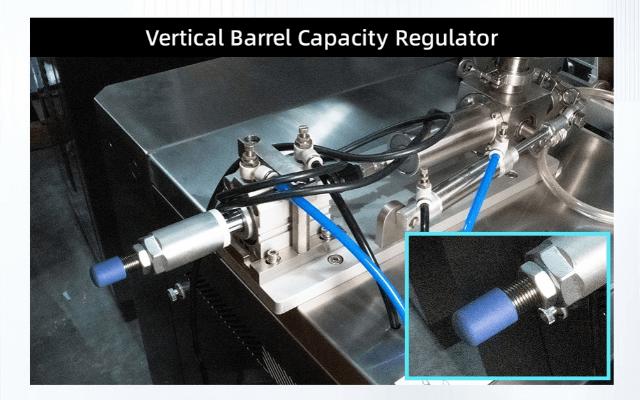

3.Vertical Barrelcapacity Requlator:

The filling capacity can be adjusted through the knobranging from approximately 3 to 100 gram

4.Horizontal constant temperature barrel:

The horizontal material barrel with a stirrer is more suitablefor thick sauces.A constant temperature system can beadded to prevent the sauces from cooling and solidifyingwhi

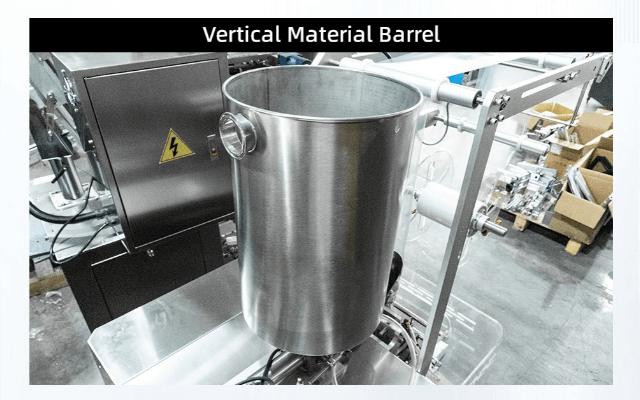

5.Vertical Material Barre:

Vertical material barrels are suitable for sauces with good fluidity

The touch screen operation PLC control drive stepper motor to control the bag length,stable performance

PID control to ensure the error range of temperature controlled within 1 degree Centigrade.

Compact Design: These machines take up less floor space, making them ideal for facilities with limited space.

Versatility: Capable of handling a wide range of sauce viscosities, from thin liquids to thick, chunky sauces.

Precision: Equipped with advanced control systems to ensure accurate filling and sealing.

|

YS-61J Ketchup and chili sauce packaging machine |

|

Technical Parameters |

1-100g(3-100ml) |

|

MeasuringScope |

(L):30-170mm (W):30-130mm |

|

Packing Speed |

30-60bags/min |

|

(L*W*H) |

900*1100*1900mm Dimension |

|

Weight |

300kg |

|

Total Power |

AC220V/50-60Hz/14kw |

|

Gas source |

≥0.6m/min |

|

Sealing method |

Three-side seal, four-side seal, back seal |

Automatic Filling System:

Multi-Lane Functionality:

Nozzle Design and Anti-drip Mechanism:

Adjustable Pouch/Bottle Sizes:

Heating and Mixing Components:

User-friendly Interface:

High Hygiene Standards:

Safety Features:

Product Feeding and Transfer:

Filling and Sealing:

Labeling and Coding:

Quality Control and Inspection:

Packaging and Dispensing:

Oil pouch packing machine suitable for sauce, ketchup, jam, mayonnaise, hot sauce, lotus paste, bean paste and other food fillings...

Our machines are widely used in the packaging of sauces, such as tomato sauce, chili sauce, salad sauce, and so on. Our models are complete and diverse for customers to choose from....

Our machines are widely used in the packaging of sauces, such as tomato sauce, chili sauce, salad sauce, and so on. Our models are complete and diverse for customers to choose from. can be used for various ty...

Yisen can provide you with peanut oil, olive oil, makeup removal oil, coconut oil, and other packaging solutions. you can also choose to fill the material into a zipper bag or stand bag....

Efficient and Reliable This machine has significantly increased our packing efficiency while maintaining superb reliability2024-08-15

Trustworthy Performance Dependable operation day in and day out, enhancing our production reliability.2024-08-15

Reliable Durability "Built to last! We've been using it daily for months without any issues. Its robust build gives us peace of mind.2024-08-09

Prompt Customer Support "Their customer service team is responsive and knowledgeable. They helped us set up and troubleshoot efficiently.2024-08-09