![]() نموذج:

YS-61J

نموذج:

YS-61J

![]() سرعة:

30-60 كيس/دقيقة

سرعة:

30-60 كيس/دقيقة

![]() حجم الحقيبة:

(الطول): 30-170 مم (العرض): 30-130 مم

حجم الحقيبة:

(الطول): 30-170 مم (العرض): 30-130 مم

![]() فيلم الاشياء:

مواد التعبئة والتغليف: BOPP/بولي إيثيلين، ألومنيوم/بولي إيثيلين، ورق/بوليفيثايلين. الملمع/الملمع/البوليفثيلين/البوليفثيلين وهلم جرا

فيلم الاشياء:

مواد التعبئة والتغليف: BOPP/بولي إيثيلين، ألومنيوم/بولي إيثيلين، ورق/بوليفيثايلين. الملمع/الملمع/البوليفثيلين/البوليفثيلين وهلم جرا

![]() مصدر الغاز:

≥ 0.6 ميجا باسكال

مصدر الغاز:

≥ 0.6 ميجا باسكال

![]() شكل الحقيبة:

ختم خلفي، ختم ثلاثي جانبي، ختم رباعي جانبي

شكل الحقيبة:

ختم خلفي، ختم ثلاثي جانبي، ختم رباعي جانبي

![]() حجم الآلة:

900*1100*1900 مم

حجم الآلة:

900*1100*1900 مم

![]() وزن:

300 كجم

وزن:

300 كجم

![]() نطاق وزن العبوة:

3-100 مل (قابلة للتخصيص)

نطاق وزن العبوة:

3-100 مل (قابلة للتخصيص)

![]() شهادة:

CE,ISO,SGS

شهادة:

CE,ISO,SGS

أنواع الأكياس:

تُستخدم ماكيناتنا على نطاق واسع في تعبئة الصلصات، مثل صلصة الطماطم، وصلصة الفلفل الحار، وصلصة السلطة، وما إلى ذلك. نماذجنا كاملة ومتنوعة للعملاء للاختيار من بينها.

مادة الفيلم :

بولي بروبيلين/بولي إيثيلين، رقائق ألومنيوم/بولي إيثيلين.

1- شاشة تعمل باللمس PLC :

شاشة تحكم ذكية تعمل باللمس، يمكنها ضبط درجة الحرارة وحجم العبوة ووزن العبوة

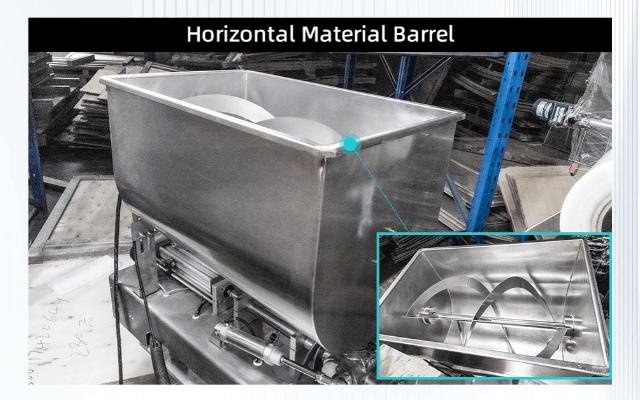

2- سعة برميل المواد الأفقية :

جهاز الاسترداديمكن ضبط سعة التعبئة بواسطة القرص الدوار، بمدى يتراوح بين 3 إلى 100 جرام تقريبًا

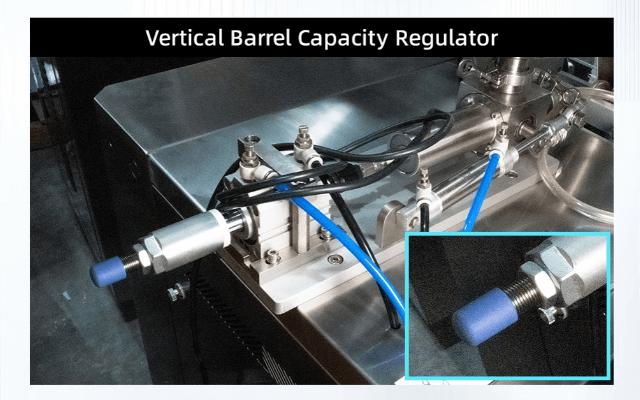

3-محدد سعة الماسورة الرأسية :

يمكن ضبط سعة التعبئة من خلال مقبض يتراوح من 3 إلى 100 جرام تقريبًا

4- برميل درجة حرارة ثابتة أفقية : برميل درجة حرارة ثابتة

يعتبر برميل المواد الأفقي المزود بأداة تقليب أكثر ملاءمة للصلصات السميكة، ويمكن إضافة نظام درجة حرارة ثابتة لمنع الصلصات من التبريد والتصلب

5- براميل المواد العمودية :

براميل المواد العمودية مناسبة للصلصات ذات السيولة الجيدة

شاشة تعمل باللمس PLC للتحكم في محرك السائر للتحكم في طول الكيس والأداء المستقر

تحكم PID لضمان التحكم في نطاق الخطأ في درجة الحرارة التي يتم التحكم فيها في حدود 1 درجة مئوية.

تصميم مدمج: تشغل هذه الماكينات مساحة أرضية أقل، مما يجعلها مثالية للمنشآت ذات المساحة المحدودة.

متعددة الاستخدامات: قادرة على التعامل مع مجموعة واسعة من لزوجة الصلصة، من السوائل الرقيقة إلى الصلصات السميكة والمكتنزة.

الدقة: مجهزة بأنظمة تحكم متطورة لضمان دقة التعبئة والختم.

|

آلة تغليف الكاتشب وصلصة الفلفل الحار YS-61J |

|

المعلمات التقنية |

1-100 جم (3-100 مل) |

|

قياسالمنظار |

(طول): 30-170 مم (العرض): 30-130 مم |

|

سرعة التعبئة |

30-60 كيس/دقيقة |

|

(الطول * العرض * الارتفاع) |

900*1100*1900 مم الأبعاد |

|

الوزن |

300 كجم |

|

إجمالي الطاقة |

تيار متردد 220 فولت / 50-60 هرتز / 14 كيلو واط |

|

مصدر الغاز |

≥ 0.6 م/دقيقة |

|

طريقة الختم |

ختم ثلاثي الجوانب، ختم رباعي الجوانب، ختم خلفي |

أحجام أكياس/زجاجات قابلة للتعديل:

مرونة لملء أحجام التعبئة المختلفة، سواء في أكياس أو أكياس أو زجاجات، مما يسمح بتعبئة أحجام مختلفة من المنتجات في نفس الماكينة.

مكونات التسخين والخلط:

تساعد خيارات التسخين المدمجة في الحفاظ على تدفق الصلصة إذا لزم الأمر.

أنظمة التقليب تضمن قوامًا متساويًا وتمنع انفصال المكونات.

واجهة سهلة الاستخدام:

شاشات عرض تعمل باللمس وعناصر تحكم سهلة التنقل، وغالبًا ما تكون مزودة بوظائف ذاكرة الوصفات للصلصات المختلفة.

معايير نظافة عالية:

يقلل الفولاذ المقاوم للصدأ والمواد الغذائية من التلوث.

قد تحتوي بعض الآلات على أنظمة التنظيف المكاني (CIP) لسهولة التنظيف.

ميزات السلامة:

مجهزة بأجهزة استشعار للكشف عن الانحشار أو الأعطال.

أزرار إيقاف الطوارئ وأغطية واقية لسلامة المشغل.

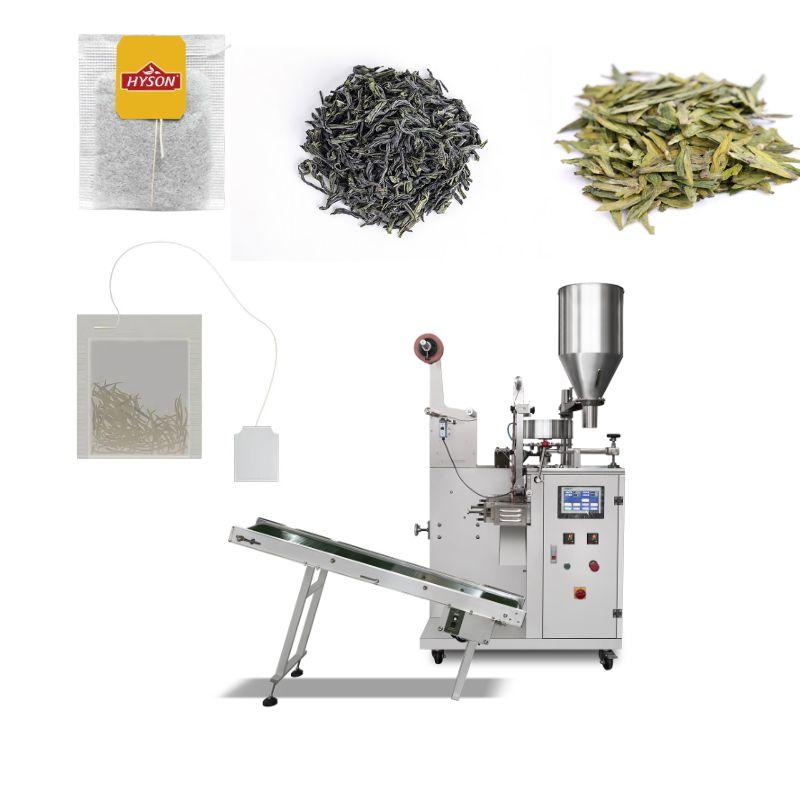

YS-66 مناسب لتعبئة الشاي الأخضر والشاي المكسور والشاي الأسود وما إلى ذلك....

نوع الفرن، التعبئة السريعة، التعبئة والتغليف السلس...

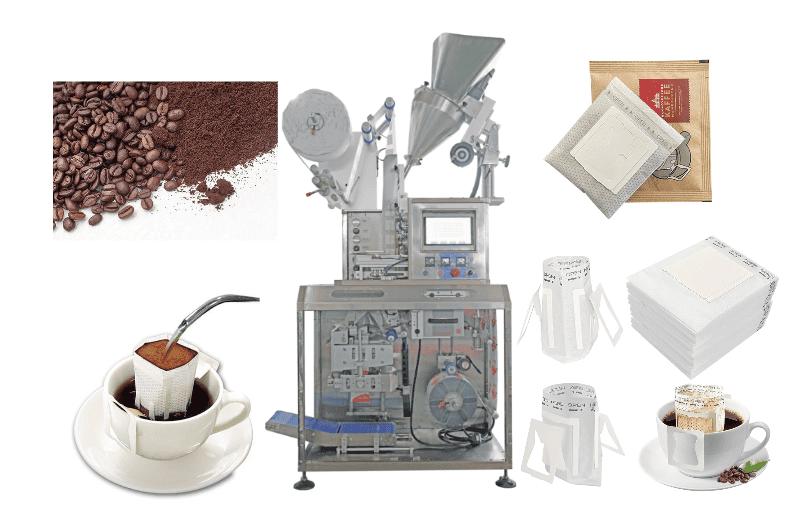

التطبيق: لا يعد YS-188X مناسبًا لتغليف القهوة المقطرة فحسب، بل يمكن استخدامه أيضًا على نطاق واسع في التغ...