![]() نموذج:

YS-80Y

نموذج:

YS-80Y

![]() سرعة:

15-30 كيس/دقيقة

سرعة:

15-30 كيس/دقيقة

![]() حجم الحقيبة:

الطول: 60-280 مم العرض: 60-200 مم

حجم الحقيبة:

الطول: 60-280 مم العرض: 60-200 مم

![]() فيلم الاشياء:

BOPP/بولي إيثيلين، ألومنيوم/بولي إيثيلين، ورق/بولي إيثيلين، ورق/بولي إيثيلين، ورق الترشيح

فيلم الاشياء:

BOPP/بولي إيثيلين، ألومنيوم/بولي إيثيلين، ورق/بولي إيثيلين، ورق/بولي إيثيلين، ورق الترشيح

![]() مصدر الغاز:

≥ 0.6 ميجا باسكال

مصدر الغاز:

≥ 0.6 ميجا باسكال

![]() شكل الحقيبة:

ختم خلفي، ختم ثلاثي جانبي، ختم رباعي جانبي

شكل الحقيبة:

ختم خلفي، ختم ثلاثي جانبي، ختم رباعي جانبي

![]() حجم الآلة:

850*1100*1900 مم

حجم الآلة:

850*1100*1900 مم

![]() وزن:

350 كجم

وزن:

350 كجم

![]() نطاق وزن العبوة:

100-1000 مل

نطاق وزن العبوة:

100-1000 مل

![]() شهادة:

CE,ISO,SGS

شهادة:

CE,ISO,SGS

Bag Types:

مادة الفيلم :

بولي بروبيلين/بولي إيثيلين، رقائق ألومنيوم/بولي إيثيلين.

شكل حقيبة التعبئة والتغليف :

ختم رباعي الجوانب، ختم ثلاثي الجوانب، ختم خلفي، كيس متصل , عبوات لاصقة

طريقة التغذية :

برميل عمودي :مناسب أكثر للصلصات/السوائل ذات السيولة الأفضل

البرميل الأفقي ذو درجة الحرارة الثابتة :مناسب للصلصات اللزجة، يمكن تعديل درجة الحرارة في البرميل لتحقيق أفضل حالة تعبئة للمنتج

1، مناسبة لقياس وتعبئة المواد السائلة والصلصة في صناعات الأغذية والأدوية والمواد الكيميائية ومستحضرات التجميل.

2، يمكن أن تكمل تلقائيًا صنع الأكياس، والقياس، والطمس، والختم، والقطع، والعد، ويمكن تهيئتها وفقًا لمتطلبات العملاء لطباعة رقم الدُفعة والوظائف الأخرى.

3 ، تشغيل شاشة تعمل باللمس ، تحكم PLC ، طول كيس التحكم المؤازر ، أداء مستقر ، تعديل سهل ، كشف دقيق. تحكم ذكي في درجة الحرارة. يضمن ضبط PID أن تكون درجة الحرارة

يتم التحكم في خطأ الدرجة في حدود 1 ℃.

|

ماكينة تعبئة صلصة أكياس الزيت السائل YS-80Y |

|

نطاق القياس |

1-1 كجم |

|

حجم الكيس |

(الطول): 60-280 مم (العرض): 50-200 مم |

|

سرعة التعبئة |

15-30 كيس/دقيقة |

| حجم الماكينة |

850 * 1100 * 1900 مم |

|

الوزن |

350 كجم |

|

الطاقة |

تيار متردد220 فولت/50-60 هرتز/1.5 كيلوواط |

|

مصدر الهواء |

0.6 م/دقيقة |

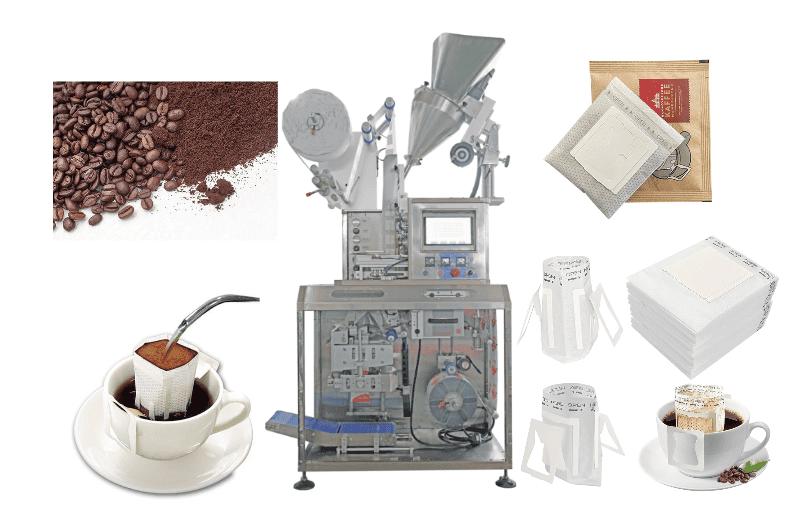

YS-66 مناسب لتعبئة الشاي الأخضر والشاي المكسور والشاي الأسود وما إلى ذلك....

التطبيق: لا يعد YS-188X مناسبًا لتغليف القهوة المقطرة فحسب، بل يمكن استخدامه أيضًا على نطاق واسع في التغ...

YS-169 مناسب لجميع أنواع الشاي المكسور، ومسحوق الشاي مثل الشاي الأسود، والشاي الأخضر، والشاي المعطر وأن...