![]() نموذج:

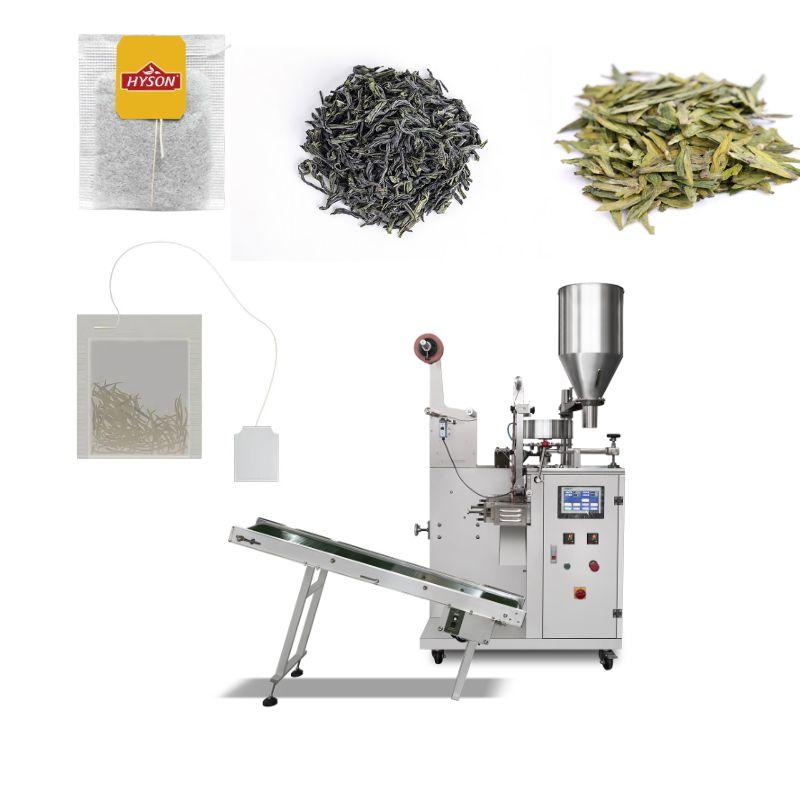

YS-61J

نموذج:

YS-61J

![]() سرعة:

30-60 كيس/دقيقة

سرعة:

30-60 كيس/دقيقة

![]() حجم الحقيبة:

(الطول): 30-170 مم (العرض): 30-130 مم

حجم الحقيبة:

(الطول): 30-170 مم (العرض): 30-130 مم

![]() فيلم الاشياء:

مواد التعبئة والتغليف: BOPP/بولي إيثيلين، ألومنيوم/بولي إيثيلين، ورق/بوليفيثايلين. الملمع/الملمع/البوليفثيلين/البوليفثيلين وهلم جرا

فيلم الاشياء:

مواد التعبئة والتغليف: BOPP/بولي إيثيلين، ألومنيوم/بولي إيثيلين، ورق/بوليفيثايلين. الملمع/الملمع/البوليفثيلين/البوليفثيلين وهلم جرا

![]() مصدر الغاز:

≥ 0.6 ميجا باسكال

مصدر الغاز:

≥ 0.6 ميجا باسكال

![]() شكل الحقيبة:

ختم خلفي، ختم ثلاثي جانبي، ختم رباعي جانبي

شكل الحقيبة:

ختم خلفي، ختم ثلاثي جانبي، ختم رباعي جانبي

![]() حجم الآلة:

900*1100*1900 مم

حجم الآلة:

900*1100*1900 مم

![]() وزن:

300 كجم

وزن:

300 كجم

![]() نطاق وزن العبوة:

1-100 جرام (قابلة للتخصيص)

نطاق وزن العبوة:

1-100 جرام (قابلة للتخصيص)

![]() شهادة:

CE,ISO,SGS

شهادة:

CE,ISO,SGS

أنواع الحقائب:

تُستخدم آلاتنا على نطاق واسع في تعبئة الصلصات، مثل صلصة الطماطم وصلصة الفلفل الحار وصلصة السلطة وما إلى ذلك. نماذجنا كاملة ومتنوعة للعملاء للاختيار من بينها.

مادة الفيلم :

بولي بروبيلين/بولي إيثيلين، رقائق ألومنيوم/بولي إيثيلين.

شكل حقيبة التعبئة والتغليف :

ختم رباعي الجوانب، ختم ثلاثي الجوانب، ختم خلفي، كيس متصل , عبوات لاصقة

طريقة التغذية :

برميل عمودي :مناسب أكثر للصلصات/السوائل ذات السيولة الأفضل

برميل درجة حرارة ثابتة أفقية للبرميل :مناسب للصلصات اللزجة، يمكن ضبط درجة الحرارة في البرميل لتحقيق أفضل حالة تغليف للمنتج

تشغيل شاشة اللمسPLC للتحكم في محرك متدرج للتحكم في طول الكيس، وأداء مستقر

التحكم في PID لضمان التحكم في نطاق الخطأ في درجة الحرارة في حدود 1 درجة مئوية.

تصميم مدمج: تشغل هذه الماكينات مساحة أرضية أقل، مما يجعلها مثالية للمنشآت ذات المساحة المحدودة.

متعددة الاستخدامات: قادرة على التعامل مع مجموعة واسعة من لزوجة الصلصة، من السوائل الرقيقة إلى الصلصات السميكة والمكتنزة.

الدقة: مجهزة بأنظمة تحكم متطورة لضمان دقة التعبئة والختم.

|

YS-61J ماكينة تعبئة وتغليف صلصة الفلفل الحار في كيس |

|

|

1-100 جم (3-100 مل) |

|

قياسالمنظار |

(طول): 30-170 مم (العرض): 30-130 مم |

|

سرعة التعبئة |

30-60 كيس/دقيقة |

|

(الطول * العرض * الارتفاع) |

900*1100*1900 مم الأبعاد |

|

الوزن |

300 كجم |

|

إجمالي الطاقة |

تيار متردد 220 فولت / 50-60 هرتز / 14 كيلو واط |

|

مصدر الغاز |

≥ 0.6 م/دقيقة |

|

طريقة الختم |

ختم ثلاثي الجوانب، ختم رباعي الجوانب، ختم خلفي |

الميزات

1.التشغيل الآلي: مؤتمتة بالكامل للتعبئة والختم والقطع والطباعة، مما يقلل من متطلبات العمالة ويزيد من الإنتاج.

2.نظام دقيق لتحديد الجرعات: يضمن تعبئة دقيقة لصلصة الفلفل الحار لكل كيس، مما يقلل من الهدر ويحافظ على التحكم في الحصص.

3.هيكل من الفولاذ المقاوم للصدأ: مصنوع عادةً من الفولاذ المقاوم للصدأ من الدرجة الغذائية، مما يضمن النظافة والمتانة وسهولة التنظيف.

4.التحكم في درجة الحرارة: أنظمة متطورة للتحكم في درجة الحرارة لاستيعاب أنواع مختلفة من مواد التعبئة والتغليف وضمان إحكام الغلق المثالي.

5.نظام تحكم PLC: يتيح سهولة ضبط المعلمات مثل حجم التعبئة وطول الكيس والسرعة، عادةً عبر شاشة تعمل باللمس.

6.فوهة مانعة للتنقيط: يمنع تقطير الصلصة أثناء التعبئة لتجنب التلوث والحفاظ على جودة التعبئة والتغليف.

7.خيارات متعددة المسارات: توفر بعض الموديلات مسارات متعددة لزيادة سرعة التعبئة ومخرجات الإنتاج.

8.متطلبات صيانة منخفضة: مصممة لسهولة الصيانة مع قطع يسهل الوصول إليها ومكونات معيارية.

الوظائف

1.التعبئة: تملأ الأكياس بدقة بكميات محددة مسبقاً من صلصة الفلفل الحار.

2.الختم: تغلق حواف الأكياس للحصول على عبوة آمنة ومقاومة للتلاعب.

3.التقطيع: تقطع الأكياس إلى أطوال محددة وتضمن فصل كل كيس بشكل نظيف.

4.ترميز الدُفعات وطباعة التاريخ: طباعة أرقام الدُفعات وتواريخ انتهاء الصلاحية مباشرةً على الأكياس.

5.كشف الأخطاء: يكتشف المشكلات مثل انخفاض مستويات الصلصة أو الأعطال، وغالبًا ما يوقف الماكينة مؤقتًا وينبه المشغل.

6.العد والإخراج: تقوم بعد الأكياس وتنظيمها لتسهيل تجميعها وتعبئتها في صناديق أو علب كرتونية أكبر.

YS-169 مناسب لجميع أنواع الشاي المكسور، ومسحوق الشاي مثل الشاي الأسود، والشاي الأخضر، والشاي المعطر وأن...

YS-66 مناسب لتعبئة الشاي الأخضر والشاي المكسور والشاي الأسود وما إلى ذلك....

نوع الفرن، التعبئة السريعة، التعبئة والتغليف السلس...