![]() Modelo:

YS-80K

Modelo:

YS-80K

![]() Velocidad:

15-30 BOLSAS/MIN

Velocidad:

15-30 BOLSAS/MIN

![]() Tamaño de la bolsa:

Longitud:40-250mm Anchura:40-200mm

Tamaño de la bolsa:

Longitud:40-250mm Anchura:40-200mm

![]() Película La Materia:

Película compuesta de PE, como: aluminio puro, aluminizado y otras bolsas prefabricadas

Película La Materia:

Película compuesta de PE, como: aluminio puro, aluminizado y otras bolsas prefabricadas

![]() Fuente de gas:

≥0.6Mpa

Fuente de gas:

≥0.6Mpa

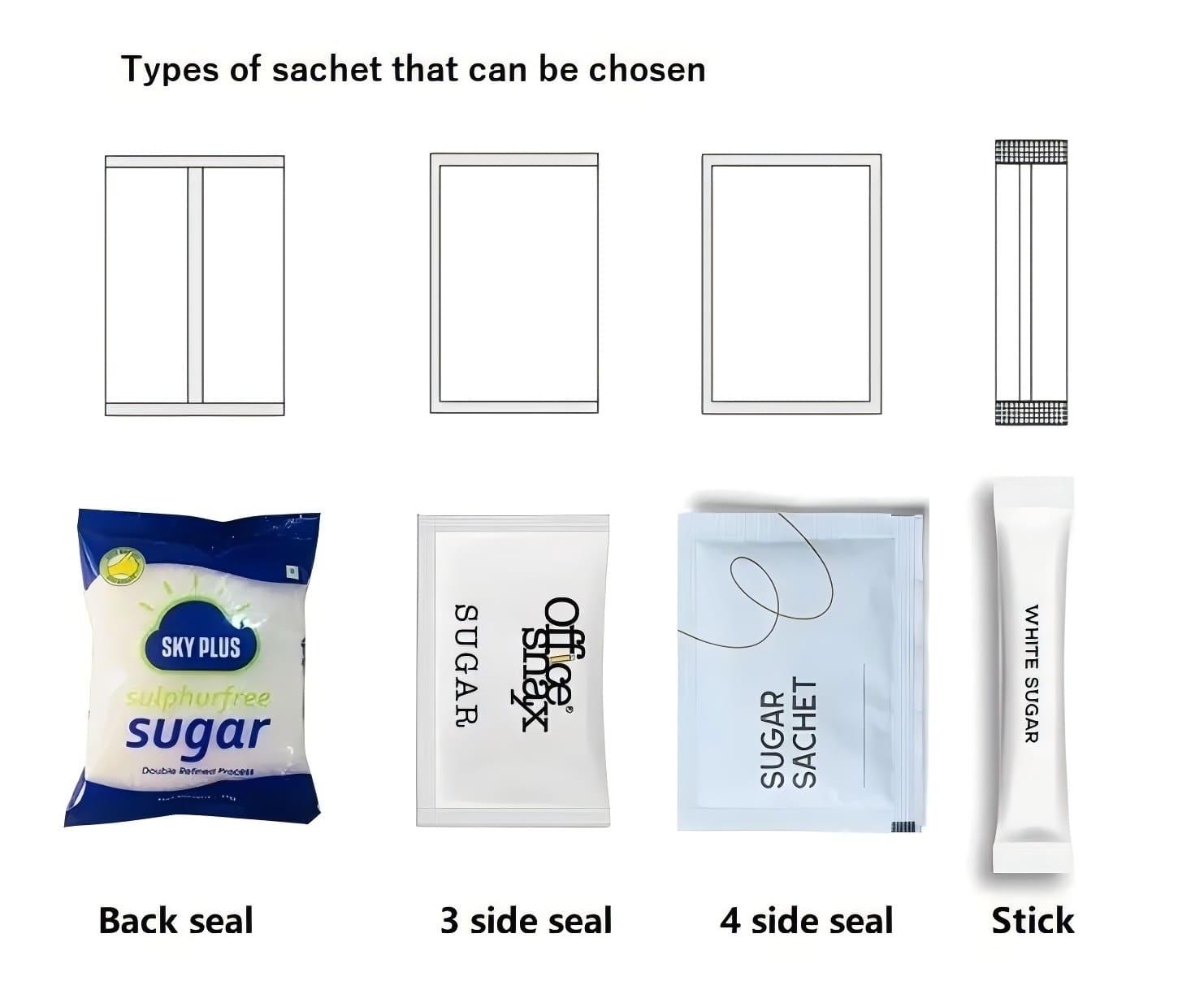

![]() Forma de la bolsa:

Junta trasera, junta de tres lados, junta de cuatro lados

Forma de la bolsa:

Junta trasera, junta de tres lados, junta de cuatro lados

![]() Tamaño de la máquina:

970mm*900mm*1900mm

Tamaño de la máquina:

970mm*900mm*1900mm

![]() Peso:

350kg

Peso:

350kg

![]() Rango de peso del paquete:

100-1000g

Rango de peso del paquete:

100-1000g

![]() Certificación:

CE,ISO,SGS

Certificación:

CE,ISO,SGS

La envasadora vertical de azúcar YS-80K ofrece una solución eficaz y de alta velocidad para envasar azúcar blanco en cantidades de 100 g a 1.000 g, utilizando película en rollo en lugar de bolsas prefabricadas. Diseñada con un sistema de llenado volumétrico de vasos, esta máquina es ideal para productos granulados como el azúcar, ya que garantiza un llenado uniforme y tamaños de envasado flexibles.

| Máquina envasadora de azúcar YS-80K de 100 g a 1 kg |

|

Gama de embalajes |

100g-1000g(depende de la densidad del material) |

|

Tamaño de la bolsa |

(L):40-250mm (W):40-200mm |

|

Velocidad |

15-30 BOLSAS /MIN |

|

Dimensión(L*W*H) |

970mm*900mm*1900mm |

|

Peso de la máquina |

350kg |

|

Potencia |

AC220V150-60HZ11.4KW |

|

Fuente de gas |

≥0.6Mpa |

|

Tipo de bolsa |

Sellado posterior/Sellado por tres lados |

|

Material de la película de embalaje |

BOPP/Polvethylene Aluminio/Polvethylene Papel/Polvethylene.Polvester/Aluminizer/Polvethvlene y así o |

Solución de envasado de azúcar YS-80K (100-1000 g), con llenadora volumétrica de vasos y envasado en rollo de película

La envasadora YS-80K ofrece una solución eficaz y de alta velocidad para envasar azúcar blanco en cantidades de 100 g a 1.000 g, utilizando rollos de película en lugar de bolsas prefabricadas. Diseñada con un sistema de llenado volumétrico de vasos, esta máquina es ideal para productos granulados como el azúcar, ya que garantiza un llenado uniforme y tamaños de envasado flexibles.

YS-169 es adecuado para todo tipo de té partido, té en polvo como té negro, té verde, té perfumado y otros tés mixtos....

YS-66 is suitable for packaging green tea, broken tea, black tea, etc....

La máquina de bolsitas de té Pyramid tiene un sistema de pesaje preciso, ideal para su uso (como té negro, té verde, té perfumado, té a granel, etc.) y puede usarse en combinació...