![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-SP160

Model:

YS-SP160

![]() Speed:

10-30BAGS/MIN

Speed:

10-30BAGS/MIN

![]() Bag Size:

Length:100-220mm Width:80-160mm

Bag Size:

Length:100-220mm Width:80-160mm

![]() Film Material:

Any premade pouch such as Stand-up bag, Stand-up bagwith zip, Back-sealed bag, Gusset bag, 3-sides-sealed bag, 4-sides-sealed bag, 8-sides-sealed bag Self-sealed bag etc.

Film Material:

Any premade pouch such as Stand-up bag, Stand-up bagwith zip, Back-sealed bag, Gusset bag, 3-sides-sealed bag, 4-sides-sealed bag, 8-sides-sealed bag Self-sealed bag etc.

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Any premade pouch such as Stand-up bag, Stand-up bagwith zip, Back-sealed bag, Gusset bag, 3-sides-sealed bag, 4-sides-sealed bag, 8-sides-sealed bag Self-sealed bag etc.

Bag Shape:

Any premade pouch such as Stand-up bag, Stand-up bagwith zip, Back-sealed bag, Gusset bag, 3-sides-sealed bag, 4-sides-sealed bag, 8-sides-sealed bag Self-sealed bag etc.

![]() Pack Weight Range:

100-500ml

Pack Weight Range:

100-500ml

![]() Machine Size:

1424*980*1343mm

Machine Size:

1424*980*1343mm

![]() Machine Weight:

450kg

Machine Weight:

450kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

One-stop solution: We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

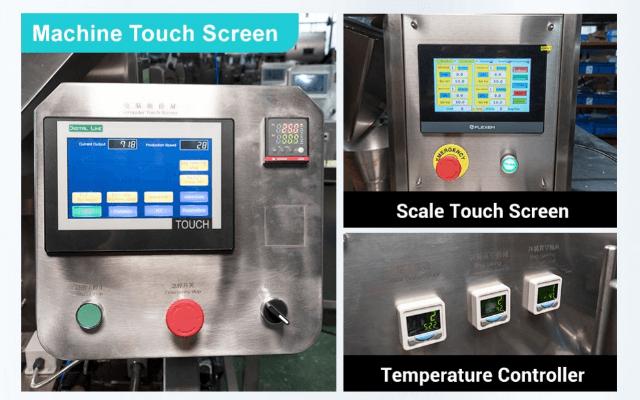

1.Machine Touch Screen

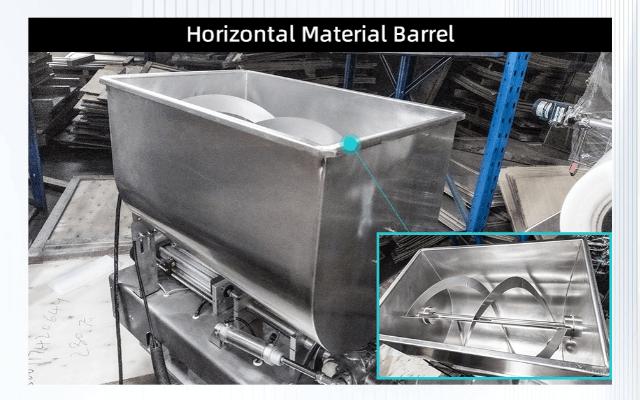

2.Horizontal constant temperature barrel:The horizontal material barrel with a stirrer is more suitablefor thick sauces.A constant temperature system can beadded to prevent the sauces from cooling and solidifyingwhi (1)

3.VerticalBarrelcapacity:RequlatorThe filling capacity can be adjusted through the knobranging from approximately 3 to 100 gram

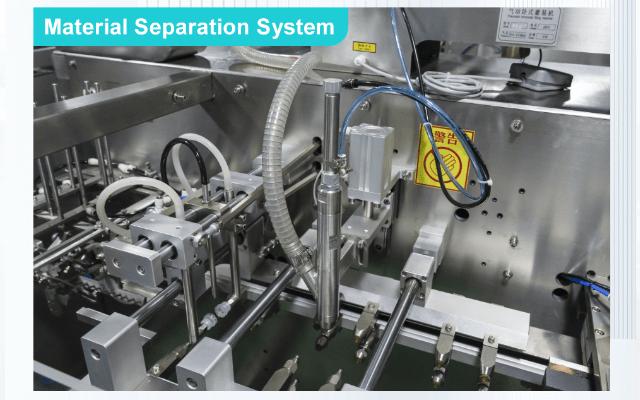

4.Material Separation System:The material separation system uses plc control system to accurately put the material into the packaging bag

5.Bag Feed System:Baa shelf lt can hold about 300 bags,An automatic alarm will activatewhen the bag runs out.The bag is picked up by the robot hand anddelivered to the designated location

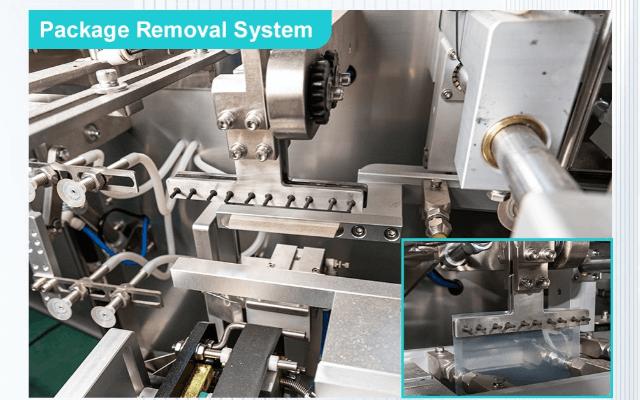

6.Package Removal System:The bag is removed from the bag rack by the manipulator andtransferred to the next step

7.Fully Automatic Bag opening system:Open the bag with a suction cup to facilitate material entry.Savesthe time of manual bag opening

| Horizontal Pre-made Pouch Doypack Packing Machine With Nozzle For Filling Liquid Products |

|

Measuring Scope |

20-500g(customizable) |

|

Packing size |

Length:100-220mm Width:80-160mm(customizable) |

|

Speed |

20-35BAGS/MIN |

|

Machine Dimension(L*W*H) |

1424*980*1343 mm |

|

Machine Weight |

450kg |

|

Total Power |

AC220V150-60HZ/2KW |

|

Gas Source |

≥0.6Mpa |

|

Bag Type |

Prefab bag |

|

PackingMaterial |

Packing material: PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags. |

1.This is a fully-automatic packing machine with Multi-function which can be integrated with various filling systems.

2.Horizontal bagging device, capable of accommodating a large number of bags

3.Servo motor to control and high speed to work.

4.Automatic alarming function and stop when the inadequate air pressure.

5. High precision horizontal bag feeding device, speed adjustable)

Pre-made Zipper bag packaging machine is suitable for many types of bags, including bags with and without zippers, as well as self-supporting bags, flat bottom bags, vacuum bags, side gusset bags, stand-up...

The YS-SP160K pre-made bag packaging machine provides an efficient, precise and intelligent solution for coffee bean packaging, especially for zipper bag packaging. The equipment integrates automatic baggi...

Application: ThsiHorizontal Pre-made Pouch Doypack Packaging Machine ( 6 Woking Stations ) is suitable for powder: milk powder, tea powder, bakery powder, spices, coffee powder, medical powder, ...

YS-180K 8-Station Premade Pouch Packaging Machine Solution for Dried Fruit Zipper Bags Application Range The YS-180K 8-station premade pouch packaging machine is specifically designed for packaging dr...

Cost-Effective Solution "It has reduced our packaging costs significantly, offering a great return on investment.2024-08-15

Excellent Customer Support "Responsive customer service that resolves any queries promptly2024-08-15