![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-SP160K

Model:

YS-SP160K

![]() Speed:

20-35BAGS/MIN

Speed:

20-35BAGS/MIN

![]() Bag Size:

Length:100-220mm Width:80-160mm

Bag Size:

Length:100-220mm Width:80-160mm

![]() Film Material:

PE composite film, such as: pure aluminum

Film Material:

PE composite film, such as: pure aluminum

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

prefabricated bags

Bag Shape:

prefabricated bags

![]() Pack Weight Range:

30-500g

Pack Weight Range:

30-500g

![]() Machine Size:

1424*980*1343mm

Machine Size:

1424*980*1343mm

![]() Machine Weight:

450kg

Machine Weight:

450kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

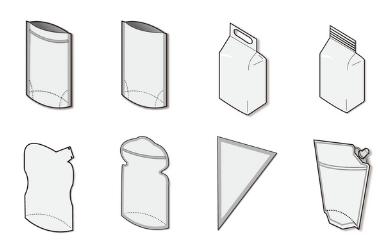

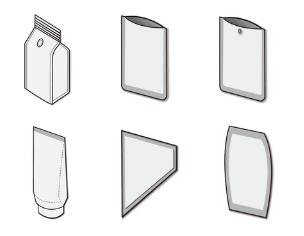

bag sample:

The pre-made Zipper bag packaging machine is suitable for many types of bags, including bags with and without zippers, as well as self-supporting bags, flat bottom bags, vacuum bags, side gusset bags, stand-up bags, custom bags, block bottom bags, four-side seal bags, special-shaped bags, zipper bags and spout bags. The equipment is powerful and can flexibly handle various bag types to meet different packaging needs

Choose the right feeder according to your product,LandPack mini premade pouch fill and seal doypack machine, is suitable for filling all kinds of granule, liquid, and powder products.

Zipper packing Machine can equip with a different metering system like a weigher, liquid pumps, auger filler, and bucket chain for different kinds of product filling and packing in premade bags.(The main machine can be equipped with different feeders to fill products.)

intelligent control touch screen:

PLC intelligent control touch screen,Can adjust the temperature.package weight.All parameters of the machine can be adjusted

Multi-station design

The pre-made Zipper bag packaging machine is equipped with a multi-station design, which can carry out multiple packaging processes at the same time to improve production efficiency. The operation ensures that each step is seamlessly connected, from bag opening, filling, sealing to finished product output. The whole process is efficient, accurate and stable, suitable for various industries such as food, medicine, and chemical industry. The operation is simple, the parameters can be set through the touch screen, and it supports multi-language switching, which greatly improves the flexibility and convenience of the equipment.

|

YS-SP160 Prefabricated Zipper bag granule packing machine |

|

Measuring Scope |

20-500g(customizable) |

|

Packing size |

Length:100-220mm Width:80-160mm(customizable) |

|

Speed |

20-35BAGS/MIN |

|

Machine Dimension(L*W*H) |

1424*980*1343 mm |

|

Machine Weight |

450kg |

|

Total Power |

AC220V150-60HZ/2KW |

|

Gas Source |

≥0.6Mpa |

|

Bag Type |

Prefab bag |

|

PackingMaterial |

Packing material: PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags. |

Automatic Pick & Place bag infeed

Multi-Language HMl

Pre-made Zipper bag packaging machine is suitable for many types of bags, including bags with and without zippers, as well as self-supporting bags, flat bottom bags, vacuum bags, side gusset bags, stand-up...

YS-SP160 premade pouch doypack packing machine is widely used in premade bag packaging for various liquid and paste in food, , chicken essence juice, tomato sauce, , jelly, food oil washing liquid etc whic...

Application: Suitable for automatic packing for grain and solid food, such as dry fruits, beans, nuts, candy, cereal, chocolate, biscuit, peanut, capsule, seeds, chemicals, sugar, etc.Different kin...

SP180K electronic scale equipped with zipper pre-made bag solution for packaging chia seeds The SP180K pre-made bag packaging machine, combined with a high-precision electronic scale, provides an efficie...

Excellent Customer Support "Responsive customer service that resolves any queries promptly2024-08-15

Cost-Effective Solution "It has reduced our packaging costs significantly, offering a great return on investment.2024-08-15