![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-65K

Model:

YS-65K

![]() Speed:

70-130bag/min

Speed:

70-130bag/min

![]() Bag Size:

Length:30-180mm Width:20-75mm

Bag Size:

Length:30-180mm Width:20-75mm

![]() Film The Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

Film The Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

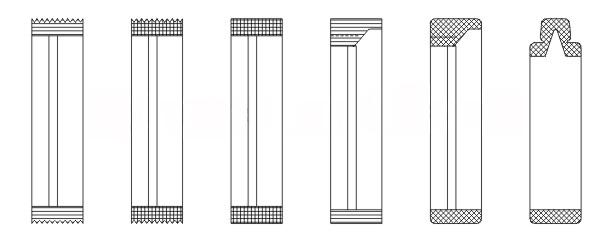

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

1-100g(customizable)

Pack Weight Range:

1-100g(customizable)

![]() Machine Size:

790*1050*1600mm

Machine Size:

790*1050*1600mm

![]() Machine Weight:

350kg

Machine Weight:

350kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

Sample:YS-65K Sugar coffee Stick packing machine Suitable for measuring and packaging of granular items in food, medicine, chemical and cosmetic industries

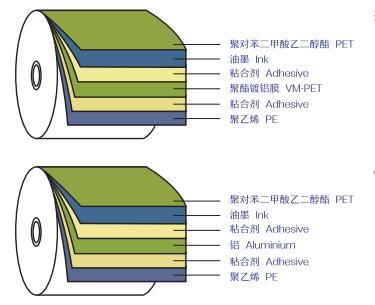

Film Material:Polypropylene/Polyethylene, Aluminum Foil/Polyethylene.

Packing bag shape:

1.Touch Screen PLC: intelligent control touch screen,Can adjust the temperature, packagesize and package weight

2.Material contact part:The material contact part is 304 stainless steel. Fast and precise dispensing of materials

3.Servo motor clamping and pulling design:the full servo motor controls the film pulling, sealing and cutting system to make the bag shape more flat and beautiful

4.Servo Motors:Servo motor controls feeding and sealing, faster and more accurate

5.Air pipe: connection The air pipe is connected to the air compressor to control the clamping and pulling of the bag. The machine pulls the film accurately and the packaging speed is faster. The clamping and pulling

6.Stainless Steel Quick Fixing Block:Consists of multiple film-penetrating shafts,the film is pulledmore smoothly and stably,and the bag is smoother and beautiful

7.Beating device:When the material goes into the former, the beater will hit the former athigh speed so that the material can enter the packaging bag more fully

8.Warning light:When a machine fails during operation, an alarm will be sounded

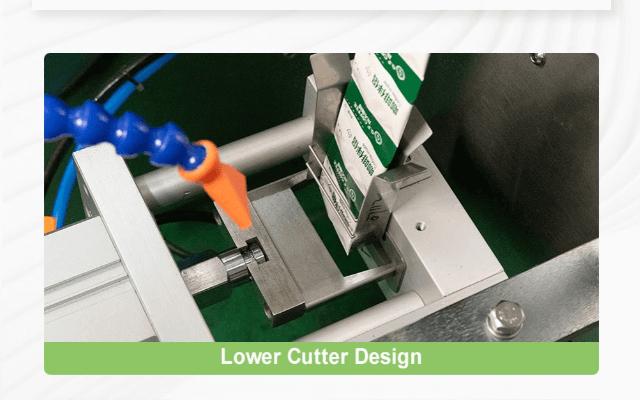

9.Lower Cutter Design:Suitable for different cutting methods such as sawtooth cuttingflat cuttinground corner cuttingspecial-shaped cutting

There is a knocking device on the former to allow the material to be put in more fully

Servo motor controls film drawing and sealing

PLC intelligent control touch screen

| YS-65K Sugar coffee Stick packing machine |

|

Pack Range |

1-100g |

|

Bag Length |

30-180mm |

|

Bag Width |

20-75mm |

|

Speed |

80-130 bags/min |

|

Machine Dimension |

790*1050*1600mm(L*W*H) |

|

Machine Weight |

300kg |

|

Air Source |

0.6Mpa |

|

Sealing Type |

Three side seal, back seal |

|

Form OfMeasurement |

Volumetric Cup System |

|

Packing Material |

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/Polyethylene Polvester/Aluminizer/Polvethvlene |

|

Material |

Food, Medicine, Chemical industry, Cosmetics industry of particlesofmeasurement packing |

YS-65K Sugar coffee Stick packing machine is a specialized machine designed to automate the process of packing coffee and sugar into single-serve sticks, typically used in cafes, hotels, or other food service settings. Here’s an overview of its key features and functions:

High-Speed Operation: These machines are often equipped to handle high-speed packing, capable of producing hundreds or even thousands of sticks per hour, depending on the model.

Compact and Modular Design: Most machines are designed to be compact, saving space in production areas, with a modular build that allows for easy adjustments, maintenance, or component replacement.

Adjustable Volume: Volume control features enable operators to adjust the quantity of sugar or coffee per stick, allowing for a range of stick sizes depending on customer requirements.

Accurate Dosing System: Advanced dosing mechanisms ensure consistent weight and avoid overfilling or underfilling, which is essential for quality control and cost-efficiency.

Multiple Lane Options: Many machines come with multi-lane setups (2-10 lanes), allowing multiple sticks to be packed simultaneously, increasing productivity.

User-Friendly Control Panel: Intuitive touchscreen control panels provide a user-friendly interface for setting and adjusting parameters, monitoring production rates, and performing diagnostics.

High-Quality Sealing: Ensures that each stick is hermetically sealed, preserving the freshness and aroma of the product while providing a neat, professional appearance.

Film Feeding System: Automatic film feeding and cutting features help maintain consistency in stick size, reducing waste and improving efficiency.

Material Compatibility: Compatible with a variety of packaging films, including polyethylene, polypropylene, aluminum laminates, and other food-grade materials, suitable for specific packaging needs.

Date Printing: Many machines come with integrated date or batch coding printers, allowing for easy product traceability and compliance with labeling regulations.

Product Filling: The machine fills pre-set amounts of sugar or coffee into stick packs with high accuracy, using a volumetric or auger filling system.

Film Pulling and Forming: The packaging film is pulled from the roll, formed into a tube shape, and sealed on one side to create the stick pack.

Sealing and Cutting: After filling, the machine seals the stick pack both longitudinally and transversely to prevent spillage. The sticks are then cut to the desired length.

Batch Coding: If equipped, the machine prints essential information, like production dates or batch codes, onto each stick pack.

Product Output: The finished stick packs are released for packing, counting, or bundling, based on the setup.

YS-65K Granule packaging machine 1.Fast and precise dispensing of materials 2.The vibration pack former can make the material fall faster,the cursorlocator keeps the graphic in the correct position on the...

YS-80K grain granule packaging machine Apply to pack bulk grain, slice, short bar material products such as whole grain, oatmeal, cereal oats, puffy food, popcorn, shrimp chip, salt, sugar, rice, sunflower...

Yisen manufacturers provide a wide range of candy packaging machines, whether it is fudge, hard sugar, single packaging, or weighing packaging, there will be a packaging solution that suits you. You can c...

Yisen machine is suitable for packaging different kinds of pet food, such as dog food, cat strips, pet cans, feed, etc. Stand-up pouch packaging has become extremely popular in the pet food industry; our ...

isen machines can pack food silica gel, synthetic silica gel, new silica gel, and other silica gel agents. The 4-sided seal or 3-sided packaging is extremely popular in the silica gel industry. We can cus...