![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-65J

Model:

YS-65J

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

Length:30-180 mm Width:40-130mm

Bag Size:

Length:30-180 mm Width:40-130mm

![]() Pack Weight Range:

1-100 ml

Pack Weight Range:

1-100 ml

![]() Film The Material:

BOPP/Polyethylene,Aluminium/PolvethylenePaper/Polvethyiene. Polvester/Aluminizer/Polvethvlene and so on

Film The Material:

BOPP/Polyethylene,Aluminium/PolvethylenePaper/Polvethyiene. Polvester/Aluminizer/Polvethvlene and so on

![]() Gas Source:

0.6Mpa

Gas Source:

0.6Mpa

![]() Bag Shape:

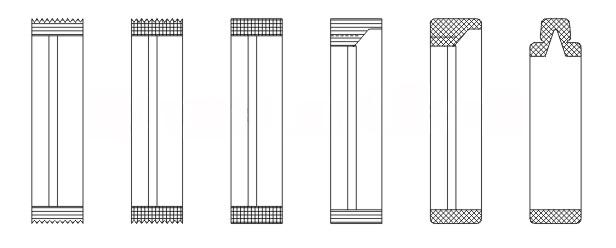

The corners can be cut,Back seal, three side seal, four side seal

Bag Shape:

The corners can be cut,Back seal, three side seal, four side seal

![]() Machine Size:

850 * 1100 * 1900 mm

Machine Size:

850 * 1100 * 1900 mm

![]() Weight:

400kg

Weight:

400kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

| S-65J Liquid Pet Cat Strip Wet Snack Food Stick Packing Machin |

|

Technical Parameters |

3-100ml |

|

Measuring Scope |

(L):30 - 180 mm (W):20-75mm |

|

Packing Speed |

30 - 60 bags/min |

|

Dimension ( L * W * H ) |

850 * 1100 * 1900 mm |

|

Weight |

400kg |

|

Total Power |

220V / 50Hz / 1.4kw |

|

Gas Source |

≥0.6 |

Key Features

Vertical Form-Fill-Seal (VFFS) Mechanism:

This machine uses a VFFS system to form stick-shaped sachets vertically, fill them with the liquid, and then seal the packaging. This approach saves space and improves packing efficiency.

High-Speed Operation:

Equipped with high-speed filling mechanisms, it can produce a large number of sachets per minute, optimizing productivity and reducing packing time.

Precise Dosing System:

Accurate dosing mechanisms ensure each sachet contains the exact quantity of liquid, minimizing product wastage and maintaining consistency across all sachets.

Easy Adjustment for Sachet Size and Volume:

Adjustable settings allow for different sachet lengths, widths, and fill volumes, accommodating various packaging needs for different product types.

Multi-Lane Packing:

Machines often have multiple lanes (2, 4, 6, or more), allowing multiple sachets to be filled and sealed simultaneously, increasing production rates.

Touchscreen Control Panel:

An intuitive touchscreen interface enables operators to set parameters, monitor operations, and troubleshoot with ease.

Servo Motor and PLC Control System:

Advanced PLC and servo motor controls provide smooth, precise movements and high repeatability for consistent results.

Hygienic Stainless Steel Construction:

The machine is usually constructed from stainless steel, ensuring compliance with food safety standards and easy cleaning to prevent contamination.

Anti-Leak Sealing Technology:

Special sealing technology prevents leaks and spillage, preserving the integrity of the product.

Automatic Product Feeding and Film Roll System:

Automated systems for film feeding and liquid filling streamline the entire process and reduce the need for manual intervention.

Film Roll Unwinding and Sachet Formation:

The machine pulls packaging film from a roll, shapes it into a sachet, and applies a heat seal on the vertical side.

Automatic Filling of Liquid Snacks:

Precisely measures and fills each sachet with a predetermined amount of liquid snack, suitable for cat treats.

Heat Sealing and Sachet Cutting:

The top and bottom of each sachet are heat-sealed, creating individual sachets. A cutting mechanism then separates the sachets from each other.

Date Coding and Batch Printing (Optional):

Integrates with printers to apply dates or batch codes on each sachet, aiding in product traceability and compliance.

The SP180 horizontal premade pouch packaging machine provides a comprehensive solution for fresh vacuum packaging. Whether it's various pouch types, different fresh products, or complex vacuum requiremen...

YS-SP180J wet pet food nozzle bag packaging machine is specifically designed to handle viscous and semi-liquid pet food products...

Wet Cat Snacks Stick Sachet Packing Machine provides an efficient and accurate cat strip packaging solution for the pet food industry, especially for the single strip packaging of soft strip products such as ...

Yisen manufacturers provide a wide range of candy packaging machines, whether it is fudge, hard sugar, single packaging, or weighing packaging, there will be a packaging solution that suits you. You can choo...

SP180K electronic scale equipped with zipper pre-made bag solution for packaging chia seeds The SP180K pre-made bag packaging machine, combined with a high-precision electronic scale, provides an efficient ...