Author:YISEN Pouch Packing Machine Manufacturer TIME:2025-03-05

In the packaging industry, prefabricated bag packaging machines have become indispensable for manufacturers looking to enhance efficiency, maintain product quality, and reduce labor costs. These machines automate the packaging process, improving speed and accuracy while minimizing waste. However, with various models and features available, selecting the right machine for your business can be challenging.

This guide outlines the key factors to consider when choosing a prefabricated bag packaging machine, ensuring you make an informed investment that meets your production requirements.

The first and most crucial step is to assess your packaging requirements. Consider the following factors:

A clear understanding of these factors will help narrow down your choices and prevent compatibility issues.

Production speed is a key determinant of overall efficiency. When selecting a prefabricated bag packaging machine, pay attention to:

Matching machine speed with your production volume ensures optimal efficiency and prevents bottlenecks in your packaging line.

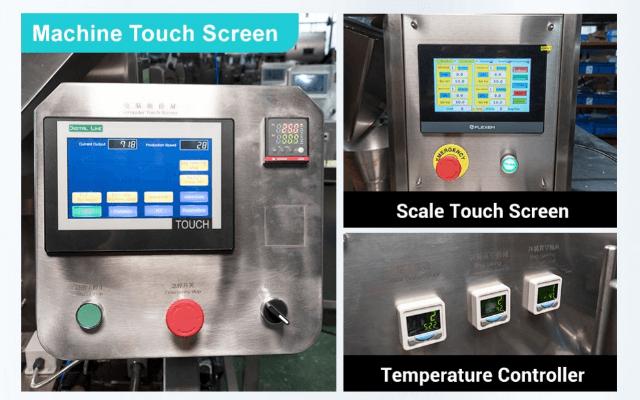

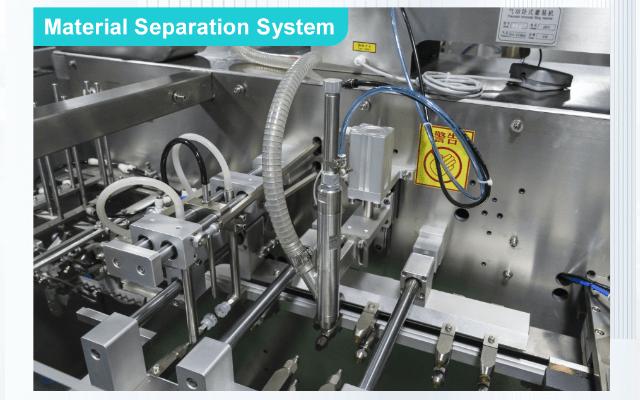

Modern prefabricated bag packaging machines incorporate automation features that enhance accuracy and reduce manual labor. Some essential features to consider include:

Investing in an automated bagging machine improves consistency, reduces human error, and lowers long-term operational costs.

A high-quality prefabricated bag packaging machine should be built with durable materials to withstand continuous operation. Key considerations include:

Additionally, check if the machine includes a warranty and service agreements for long-term reliability.

A well-designed prefabricated bag packaging machine should be easy to operate, reducing the time required for staff training. Consider:

A user-friendly design increases operational efficiency and reduces labor-intensive processes.

Regular maintenance is crucial to keeping your packaging machine running efficiently. Before purchasing, inquire about:

Choosing a supplier that provides strong after-sales service ensures quick issue resolution and minimizes production delays.

While the initial investment in a prefabricated bag packaging machine is important, consider the total cost of ownership, which includes:

A high-quality machine may have a higher upfront cost but lower long-term expenses, making it a more cost-effective choice.

The credibility of your packaging machine supplier plays a significant role in your purchasing decision. To ensure reliability:

A reputable supplier not only delivers quality machines but also provides ongoing technical support and service agreements.

Selecting the right prefabricated bag packaging machine requires careful evaluation of your packaging needs, production speed, automation features, machine quality, and vendor reliability. By considering these key factors, you can invest in a machine that enhances operational efficiency, reduces costs, and supports business growth.

Investing in the right packaging solution today will help ensure your company stays competitive in the evolving packaging industry.