![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-80K

Model:

YS-80K

![]() Speed:

15-30BAGS/MIN

Speed:

15-30BAGS/MIN

![]() Bag Size:

Length:40-250mm Width:40-200mm

Bag Size:

Length:40-250mm Width:40-200mm

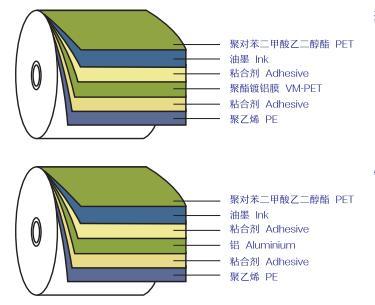

![]() Film The Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

Film The Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

5-1000g

Pack Weight Range:

5-1000g

![]() Machine Size:

970mm*900mm*1900mm

Machine Size:

970mm*900mm*1900mm

![]() Machine Weight:

350kg

Machine Weight:

350kg

![]() Certification:

CE, ISO,SGS

Certification:

CE, ISO,SGS

YS-80K grain granule packaging machine Apply to pack bulk grain, slice, short bar material products such as whole grain, oatmeal, cereal oats, puffy food, popcorn, shrimp chip, salt, sugar, rice, sunflower seed, peanut, beans, nuts, pistachio, peas, etc.

Raw material:

1.Touch ScreenPLC intelligent control touch screen,Can adjust the temperature, packagesize and package weight

2.Barrel High capacity barrel 304 stainless steel

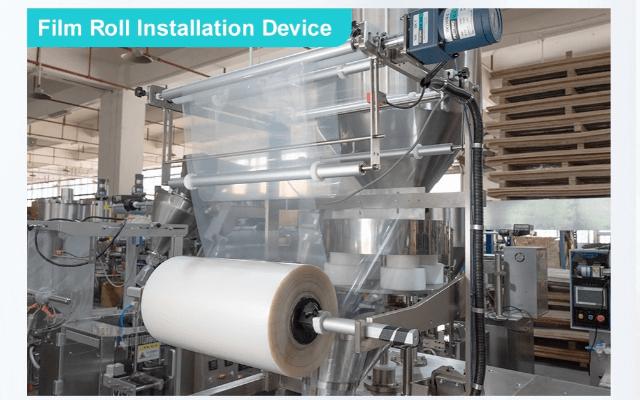

3.Film Roll Installation Device:Consists of multiple film-penetrating shafts,the film is pulled moresmoothly and stably,and the bag is smoother and beautiful

PLC intelligent control touch screen

304 Stainless Steel Silo

Servo motor controls film drawing and sealing

| YS-80K grain granule packaging machine |

|

Packing Range |

100g-1000g(depends on the material density) |

|

Bag Size |

(L):40-250mm (W):40-200mm |

|

Speed |

15-30BAGS /MIN |

|

Dimension(L*W*H) |

970mm*900mm*1900mm |

|

Machine Weight |

350kg |

|

Power |

AC220V150-60HZ11.4KW |

|

Gas Source |

≥0.6Mpa |

|

Bag Type |

Back sealing/Three sides sealing |

|

The Material Of Packing Film |

BOPP/Polvethylene Aluminium/Polvethylene Paper/Polvethylene.Polvester/Aluminizer/Polvethvlene and so or |

YS-80K Grain Granule Pouch Packaging Machine is designed to efficiently package grain or granular products like rice, beans, seeds, sugar, and other small particles into pouches. These machines can vary in complexity, but here are common features and functions often found in high-quality models:

YS-80K offer a complete solution for efficiently and consistently packaging grain and granules into ready-for-sale pouches, with customizable features to suit a range of product needs and production scales.

Detergent Packing Machine Applicable: rice, corn, pet food, coffee beans, dried fruits, popcorn, sesame, seasonings, tea, washing powder, etc....

YS-80K grain granule packaging machine Apply to pack bulk grain, slice, short bar material products such as whole grain, oatmeal, cereal oats, puffy food, popcorn, shrimp chip, salt, sugar, rice, sunflower...

80K Back-Sealed Packaging Solution for Dried Chili The 80K packaging machine provides a high-efficiency, precision-based solution for back-sealed packaging of dried chili. Designed to handle deli...

Yisen manufactures a wide range of packaging machines specifically designed for bagging, wrapping, or container-filling seeds. We will provide the best packaging solution based on the size of the customer...

Yisen manufactures a wide range of packaging machines specifically designed for bagging, wrapping, or container-filling snack foods including packaging chips, crackers, cookies, popcorn, beef jerky, nuts, ...