![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

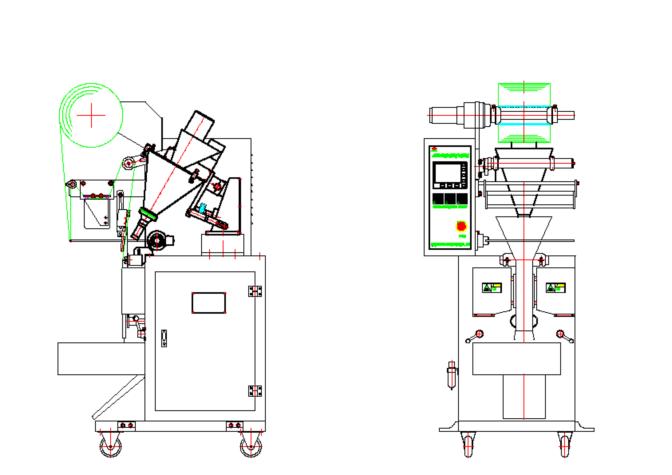

YS-FBQ100

Model:

YS-FBQ100

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

(L):50-150mm (W):25-120mm

Bag Size:

(L):50-150mm (W):25-120mm

![]() Film The Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

Film The Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

1-100g(customizable)

Pack Weight Range:

1-100g(customizable)

![]() Machine Size:

760*980*1700mm

Machine Size:

760*980*1700mm

![]() Machine Weight:

380kg

Machine Weight:

380kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

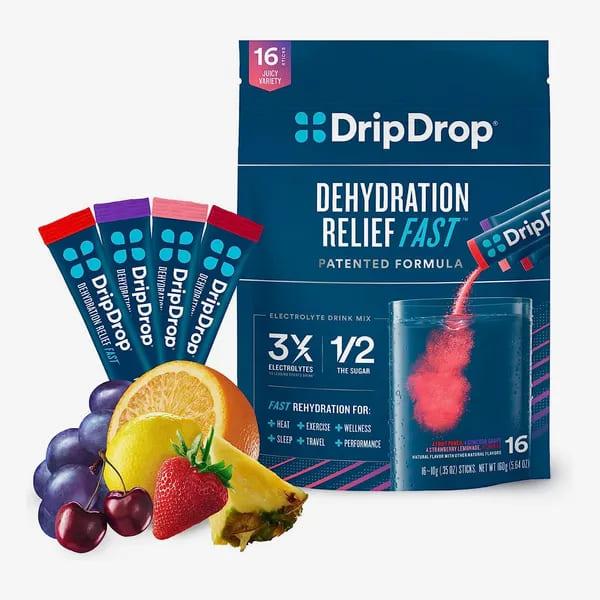

Application:Suitable for metering and packaging of powdered products in the food, medicine, chemical and cosmetic industries

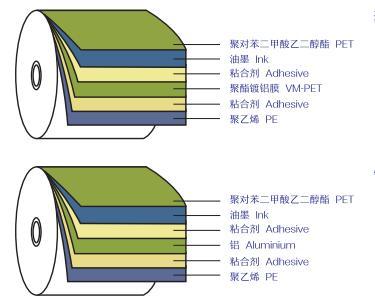

Film roll raw materials:

Machine Model:

Servo motor control, with simple operation and accurate running

|

Fully automatic powder packaging machine coffee packaging machine |

|

Bag Size |

(L):50-150mm(W):25-120mm |

|

Bag Capacity |

1-100g |

|

Packing Speed |

30-60 bags/min |

|

Power |

220V150hz 1.6KW |

|

Machine Size |

760*980*1700mm |

|

Machine weight |

300kg |

|

Sealing Type |

Three side seal, four side seal, back seal |

|

Air Source |

0.6Mpa. 100L/min |

|

Form Of Measurement |

Screw metering |

|

Packing Material |

Multilayer composite film, polyester/PE,polyester/aluminum foil/PE |

|

Suitable For The Material |

Food, medicine, chemical, daily chemical industry and other powdery materials |

Features

Automatic Filling and Sealing:

High Precision Dosing System:

Adjustable Pouch Size:

Multiple Sealing Options:

Integrated Date Printing:

Touch Screen Interface:

Stainless Steel Construction:

PLC Control System:

Error Detection and Alerts:

Nitrogen Flushing (optional):

Filling:

Pouch Feeding:

Sealing:

Cutting and Shaping:

Batch Coding:

Quality Assurance:

Data Monitoring:

Safety Features:

Multi-head Filling:

Vacuum Sealing:

Automated Bagging Options:

By integrating these features and functions, coffee powder pouch packaging machines can enhance productivity, ensure product quality, and extend the shelf life of coffee powder

YS-65F Coffee Powde Stick Packaging Machineit is suitable for many kinds of powder products, such as tea powder, medical powder, chemical powder, flour, milk powder, coffee powder, glucose, medical powder, nu...

YS-80F Sachet Powder Packing Machine suitable for fine powder material, such as spices powder, coffee powder, wheat flour, detergent powder, chilli powder, seasoning powder, etc....

The 65F powder packaging machine provides an efficient and precise packaging solution for electrolyte powder. The machine is equipped with an advanced metering system to ensure that the weight of each package...

Yisen packaging machine has a great advantage in packaging flour. It is a leading manufacturer. As long as you have demand, we will customize the best packaging solution for you. Our flour packaging scheme i...

Yisen Manufacturing has many experiences in packaging milk powder, and we will provide customers with a solution that suits them. Packing with jars is the most common packaging method in the milk powder indu...

User-Friendly Interface "The interface is so intuitive; even our new staff learned to operate it within minutes. Saves us a lot of training time!"2024-08-20

Efficient and Reliable "This machine has made our spice packing process incredibly efficient. It's reliable2024-08-20

Precision Packing "Impressed with its accuracy! Every packet is consistently filled to the exact weight we need. No more wastage2024-08-20

Quiet Operation "Surprisingly quiet during operation. Doesn't disrupt our workspace like other machines we've used."2024-08-20