![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-61F

Model:

YS-61F

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

(L):30-170 mm(W):30-130mm

Bag Size:

(L):30-170 mm(W):30-130mm

![]() Film The Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

Film The Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

1-100g(customizable)

Pack Weight Range:

1-100g(customizable)

![]() Machine Size:

900*1100*1900mm

Machine Size:

900*1100*1900mm

![]() Machine Weight:

300kg

Machine Weight:

300kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

Sample:Suitable for packaging flour, cocoa powder, protein powder, seasoning powder, Chinese medicine powder, and washing powder

Film roll material:BOPP/Polyethylene,Aluminium/Polyethyene,Paper/PolyethylenePolyester/Aluminizer/Polyethylene and so on.

Full-automatic weigh-form-fill-seal type, efficient and simple to use.

Use famous brand electric and penumatic components,stable and long life circle.

Use superior mechanical components, reduce the wear outless .

Easy to install film, auto correcting the excursion of the film .

Apply advanced operating system ,easy to use and reprogramable. To be used on Jintian High quality machine, it makes your packing work easy and efficiency.

There are two types of screw feeding:

1. Vertical screw 2. Inclined screw

The vertical screw is suitable for powders that are prone to dust and can effectively prevent the material from scattering during the process of conveying to the molding machine.

| YS-61F Vertical powder flour packaging machine |

|

Packaging range |

1 -100 g |

| Bag Size | (L):30-170 (W):30-130 mm |

|

Packaging speed |

30 - 60 bags/min |

| L*W*H |

900 * 1100 * 1900 mm |

|

weight |

350kg |

|

Total Power |

220V / 50Hz / 1.4kw |

YS-80F Sachet Powder Packing Machine suitable for fine powder material, such as spices powder, coffee powder, wheat flour, detergent powder, chilli powder, seasoning powder, etc....

Suitable for packaging flour, cocoa powder, protein powder, seasoning powder, Chinese medicine powder, and washing powder...

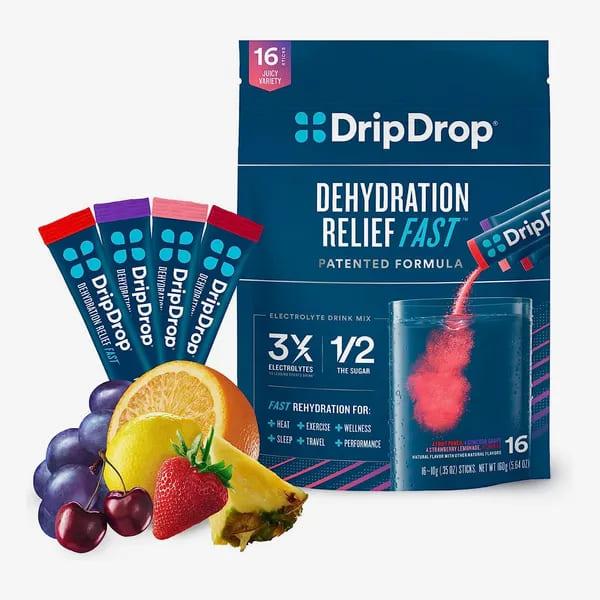

The 65F powder packaging machine provides an efficient and precise packaging solution for electrolyte powder. The machine is equipped with an advanced metering system to ensure that the weight of each package...

Yisen packaging machine has a great advantage in packaging flour. It is a leading manufacturer. As long as you have demand, we will customize the best packaging solution for you. Our flour packaging scheme i...

Yisen has been providing customers with paprika powder packaging solutions. Back seal, three-side seal, four-side seal are the most widely used packaging methods in the paprika powder industry. Customers can...

Quiet Operation "Surprisingly quiet during operation. Doesn't disrupt our workspace like other machines we've used."2024-08-20

Efficient and Reliable "This machine has made our spice packing process incredibly efficient. It's reliable2024-08-20

User-Friendly Interface "The interface is so intuitive; even our new staff learned to operate it within minutes. Saves us a lot of training time!"2024-08-20

"Uses less energy than expected. Helps keep our operational costs down without sacrificing performance2024-08-20