![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-65K

Model:

YS-65K

![]() Speed:

70-100 bag/min

Speed:

70-100 bag/min

![]() Bag Size:

Length:30-180mm Width:20-75mm

Bag Size:

Length:30-180mm Width:20-75mm

![]() Film Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

Film Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

3-100g(customizable)

Pack Weight Range:

3-100g(customizable)

![]() Machine Size:

790*1050*1600mm

Machine Size:

790*1050*1600mm

![]() Machine Weight:

350kg

Machine Weight:

350kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

Packing Exambers:

There is a knocking device on the former to allow the material to be put in more fully

Servo motor controls film drawing and sealing

PLC intelligent control touch screen

| High Speed Granule Sugar Salt Stick Filling Sealing Machine stick packaging machine |

|

Pack Range |

1-100g |

|

Bag Length |

30-180mm |

|

Bag Width |

20-75mm |

|

Speed |

80-130 bags/min |

|

Machine Dimension |

790*1050*1600mm(L*W*H) |

|

Machine Weight |

300kg |

|

Air Source |

0.6Mpa |

|

Sealing Type |

Three side seal, back seal |

|

Form OfMeasurement |

Volumetric Cup System |

|

Packing Material |

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/Polyethylene Polvester/Aluminizer/Polvethvlene |

|

Material |

Food, Medicine, Chemical industry, Cosmetics industry of particlesofmeasurement packing |

High-Speed Operation:

Multi-Lane Design:

Precision Dosing Mechanism:

Adjustable Sachet Length and Width:

Sealing Options:

User-Friendly Interface:

Automated Product Feeding:

Stainless Steel Build:

Error Detection and Safety:

Low Maintenance:

Product Feeding:

Dosing/Filling:

Pouch Forming:

Sealing:

Cutting:

Batch Coding and Printing:

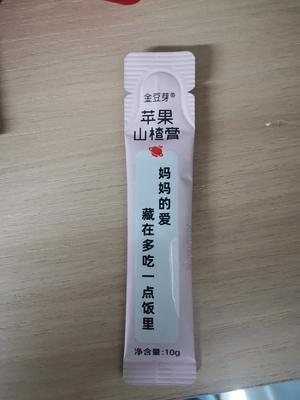

Such YS-65K stick packaging machine are widely used in industries like food, pharmaceuticals, and chemicals for products such as sugar, salt, pepper, powdered creamer, spices, and even small granulated medicines.

YS-61J Stick sachet packing machine widely applied for food,Medicine,chemical liquid products such as Mouthwash, Ketchup, flavoring, Sauce ,Pasty, Shampoo, salad dressing, cream, body wash liquid and so on...

Suitable for instant noodle industry soup bag, desiccant, powder, broken tea and other small granular items packaging Suitable for instant noodle industry soup bag, desiccant, powder,...

YS-61J Popsicle stick packing machine Suitable for packaging all kinds of liquid products, such shampoo, body wash, juice, honey, milk, mouthwash, sauce, jam, jelly and so on....

61J Packaging Solution for 4 Side Seal Sachet Cosmetic Cream, The 61J packaging machine provides an efficient and precise solution for packaging cosmetic cream in 4 side seal sachets. Designed specifically...

This machine can not only pack stick bags, but also customize solutions according to your needs....

Compact and Space-Saving "Perfect for our limited space, this machine's compact size doesn't compromise on performance. It fits seamlessly into our production line.2024-08-09

The guidance and debugging is very convenient, the machine is very stable, the after-sales service is professional and patient, and the packaging effect is good2024-08-09

User-Friendly Design "The intuitive design makes operating this sauce packaging machine a breeze. Our staff learned to use it quickly without any issues.2024-08-09

High Quality Output "We've noticed a consistent quality in our sauce packaging since using this machine. It delivers perfectly sealed packets every time.2024-08-09