![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-61J

Model:

YS-61J

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

Length:30-170mm Width:30-130

Bag Size:

Length:30-170mm Width:30-130

![]() Film Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

Film Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

3-100ml(customizable)

Pack Weight Range:

3-100ml(customizable)

![]() Machine Size:

900 * 1100 * 1900mm

Machine Size:

900 * 1100 * 1900mm

![]() Machine Weight:

300kg

Machine Weight:

300kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

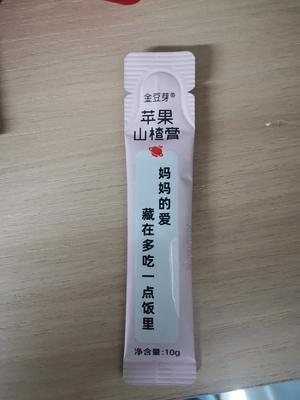

Bag Types:

Film Material:Polypropylene/Polyethylene, Aluminum Foil/Polyethylene.

Packing bag shape:Four-side seal, three-side seal, back seal, continuous bag,stick packs

Feeding method:

Vertical barrel:More suitable for sauces/liquids with better fluidity

Horizontal constant temperature barrel:Suitable for viscous sauces, the temperature in the barrel can be adjusted to achieve the best packaging state for the product

The touch screen operationPLC controldrive stepper motor to control the bag length,stable performance

PID control to ensure the error range of temperature controlled within 1degree Centigrade.

Compact Design: These machines take up less floor space, making them ideal for facilities with limited space.

Versatility: Capable of handling a wide range of sauce viscosities, from thin liquids to thick, chunky sauces.

Precision: Equipped with advanced control systems to ensure accurate filling and sealing.

|

Automatic Popsicle stick packing machine |

|

Technical Parameters |

1-100g(3-100ml) |

|

MeasuringScope |

(L):30-170mm (W):30-130mm |

|

Packing Speed |

30-60bags/min |

|

(L*W*H) |

900*1100*1900mm Dimension |

|

Weight |

300kg |

|

Total Power |

AC220V/50-60Hz/14kw |

|

Gas source |

≥0.6m/min |

|

Sealing method |

Three-side seal, four-side seal, back seal |

YS-65F powder stick bag Packing machine is suitable for many kinds of powder products, such as tea powder, medical powder, chemical powder, flour, milk powder, coffee powder, glucose, medical powder, nutri...

it is suitable for many kinds of powder products, such as tea powder, medical powder, chemical powder, flour, milk powder, coffee powder, glucose, medical powder, nutrition powder, etc....

YS-65K Stick packaging machine Suitable for measuring and packaging of granular items in food, medicine, chemical and cosmetic industries...

Application: High-speed multi-lane fine granule sugar salt stick filling sealing machine suitable for kinds of loose granule products such as sugar, salt, small grains, seeds, spice, sesame, seasoning,...

This machine can not only pack stick bags, but also customize solutions according to your needs....

User-Friendly Design "The intuitive design makes operating this sauce packaging machine a breeze. Our staff learned to use it quickly without any issues.2024-08-09

The guidance and debugging is very convenient, the machine is very stable, the after-sales service is professional and patient, and the packaging effect is good2024-08-09

Compact and Space-Saving "Perfect for our limited space, this machine's compact size doesn't compromise on performance. It fits seamlessly into our production line.2024-08-09

High Quality Output "We've noticed a consistent quality in our sauce packaging since using this machine. It delivers perfectly sealed packets every time.2024-08-09