![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-65J

Model:

YS-65J

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

Length:30-180 mm Width:40-130mm

Bag Size:

Length:30-180 mm Width:40-130mm

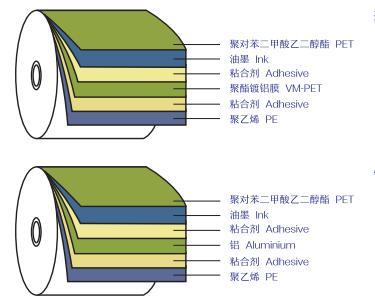

![]() Film Material:

Packing material:BOPP/Polyethylene,Aluminium/PolvethylenePaper/Polvethyiene. Polvester/Aluminizer/Polvethvlene and so on

Film Material:

Packing material:BOPP/Polyethylene,Aluminium/PolvethylenePaper/Polvethyiene. Polvester/Aluminizer/Polvethvlene and so on

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

3-100ml(customizable)

Pack Weight Range:

3-100ml(customizable)

![]() Machine Size:

850 * 1100 * 1900 mm

Machine Size:

850 * 1100 * 1900 mm

![]() Machine Weight:

400kg

Machine Weight:

400kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

Sample: Suitable for hand sanitizer, disinfectant, honey, milk, jam, ketchup, salad dressing, shampoo, shampoo, vinegar, soy sauce, etc

Packing bag shape:

raw material:

Constant temperature horizontal barrel/vertical barrel:

vertical barrel:More suitable for sauces/liquids with better fluidity

Constant temperature horizontal barrel:suitable for viscous sauces, the temperature in the barrel can be adjusted to achieve

the best packaging state for the product

Film pulling and clamping type: Servo motor controls the film pulling and clamping to make the packaging smoother and more beautiful

|

YS-65J honey packaging machine Servo packaging machine |

|

Technical Parameters |

3-100ml |

|

Measuring Scope |

(L):30 - 180 mm (W):20-75mm |

|

Packing Speed |

30 - 60 bags/min |

|

Dimension ( L * W * H ) |

850 * 1100 * 1900 mm |

|

Weight |

400kg |

|

Total Power |

220V / 50Hz / 1.4kw |

|

Gas Source |

≥0.6 |

Viscous Product Handling:

Automatic Filling System:

Heat Sealing:

Film Roll Handling:

PLC Control System:

Sanitary Design:

Batch Coding:

Compact Footprint:

Product Feeding:

Forming and Filling:

Sealing and Cutting:

Packaging Speed Control:

Weight Control:

Alarming & Fault Detection:

YS-99B Sachet sport gel packing machine it is machine can automatically pack some liqiud, powder and granule materials, such as energy gels, cream, honey and paste materials in chemical, medical and food ind...

Our sauce packaging machine are widely used in the packaging of sauces, such as tomato sauce, chili sauce, salad sauce, and so on. Our models are complete and diverse for customers to choose from....

Our machines are widely used in the packaging of sauces, such as tomato sauce, chili sauce, salad sauce, and so on. Our models are complete and diverse for customers to choose from. can be used for various ty...

Yisen machines are widely used for detergent packaging, including laundry fluids, detergents, cleaners, etc. As long as you have demand, we will customize the most suitable packaging solution for you....

The ketchup packaging is not bad2024-08-09

Efficient and Reliable This machine has significantly increased our packing efficiency while maintaining superb reliability2024-08-15

Trustworthy Performance Dependable operation day in and day out, enhancing our production reliability.2024-08-15

Prompt Customer Support "Their customer service team is responsive and knowledgeable. They helped us set up and troubleshoot efficiently.2024-08-09