![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-65J

Model:

YS-65J

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

Length:30-180 mm Width:40-130mm

Bag Size:

Length:30-180 mm Width:40-130mm

![]() Film Material:

Packing material:BOPP/Polyethylene,Aluminium/PolvethylenePaper/Polvethyiene. Polvester/Aluminizer/Polvethvlene and so on

Film Material:

Packing material:BOPP/Polyethylene,Aluminium/PolvethylenePaper/Polvethyiene. Polvester/Aluminizer/Polvethvlene and so on

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

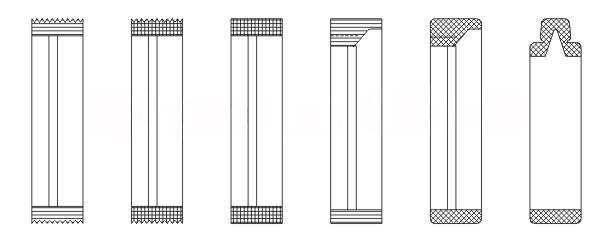

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

1-100ml(customizable)

Pack Weight Range:

1-100ml(customizable)

![]() Machine Size:

850 * 1100 * 1900 mm

Machine Size:

850 * 1100 * 1900 mm

![]() Machine Weight:

400kg

Machine Weight:

400kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

YS-65 Sauce Packaging Machine Solution for Sealed Bags of Facial Cream Cosmetics

The YS-65 sauce packaging machine offers an efficient and precise solution for packaging facial cream cosmetics in sealed bags. Designed for the cosmetic industry, this machine ensures that your products are packaged securely while maintaining their quality and freshness.

High Precision Filling

The YS-65 is equipped with an advanced filling system that accurately dispenses the required amount of facial cream into each bag, minimizing waste and ensuring product consistency.

Sealed Bag Design

The machine produces sealed bags that protect the facial cream from air and moisture, preserving the integrity and effectiveness of the product over time.

Fully Automated Operation

With automated feeding, filling, sealing, and cutting processes, the YS-65 enhances production efficiency while reducing labor costs and the risk of errors.

Flexible Bag Sizes

The YS-65 can accommodate various bag sizes, making it adaptable to different product volumes. It easily switches between small sample sizes and larger retail packages.

User-Friendly Interface

The PLC control system and intuitive touchscreen make it easy to set parameters and monitor production, streamlining operations and reducing training time.

Durable Construction

Built with high-quality materials, the YS-65 is designed for reliable performance in high-volume production environments, ensuring long-lasting use.

The YS-65 packaging machine is ideal for packaging a wide range of cosmetic products, including facial creams, lotions, and serums. Its sealed bag capability is perfect for maintaining product freshness and quality.

With the YS-65, your facial cream packaging process will be efficient, reliable, and visually appealing, helping to enhance your brand’s presence in the competitive cosmetics market.

| YS-65J Four side sealed bag for facial cream cosmetics |

|

Technical Parameters |

3-100ml |

|

Measuring Scope |

(L):30 - 180 mm (W):20-75mm |

|

Packing Speed |

30 - 60 bags/min |

|

Dimension ( L * W * H ) |

850 * 1100 * 1900 mm |

|

Weight |

400kg |

|

Total Power |

220V / 50Hz / 1.4kw |

|

Gas Source |

≥0.6 |

Oil pouch packing machine suitable for sauce, ketchup, jam, mayonnaise, hot sauce, lotus paste, bean paste and other food fillings...

YS-65 Sauce Packaging Machine Solution for Sealed Bags of Facial Cream Cosmetics The YS-65 sauce packaging machine offers an efficient and precise solution for packaging facial cream cosmetics in sealed bag...

Our machines are widely used in the packaging of sauces, such as tomato sauce, chili sauce, salad sauce, and so on. Our models are complete and diverse for customers to choose from. can be used for various ty...

Yisen machines are widely used for detergent packaging, including laundry fluids, detergents, cleaners, etc. As long as you have demand, we will customize the most suitable packaging solution for you....

Reliable Durability "Built to last! We've been using it daily for months without any issues. Its robust build gives us peace of mind.2024-08-09

Efficient and Reliable This machine has significantly increased our packing efficiency while maintaining superb reliability2024-08-15

Trustworthy Performance Dependable operation day in and day out, enhancing our production reliability.2024-08-15

The ketchup packaging is not bad2024-08-09