![]() نموذج:

YS-65K

نموذج:

YS-65K

![]() سرعة:

70-100 كيس/دقيقة

سرعة:

70-100 كيس/دقيقة

![]() حجم الحقيبة:

الطول: 30-180 مم العرض: 20-75 مم

حجم الحقيبة:

الطول: 30-180 مم العرض: 20-75 مم

![]() فيلم الاشياء:

فيلم PE المركب، مثل: الألومنيوم النقي والألومنيوم المطلي بالألومنيوم وغيرها من الأكياس الجاهزة

فيلم الاشياء:

فيلم PE المركب، مثل: الألومنيوم النقي والألومنيوم المطلي بالألومنيوم وغيرها من الأكياس الجاهزة

![]() مصدر الغاز:

≥ 0.6 ميجا باسكال

مصدر الغاز:

≥ 0.6 ميجا باسكال

![]() شكل الحقيبة:

ختم خلفي، ختم ثلاثي جانبي، ختم رباعي جانبي

شكل الحقيبة:

ختم خلفي، ختم ثلاثي جانبي، ختم رباعي جانبي

![]() حجم الآلة:

790*1050*1600 مم

حجم الآلة:

790*1050*1600 مم

![]() وزن:

350 كجم

وزن:

350 كجم

![]() نطاق وزن العبوة:

3-100 جرام (قابلة للتخصيص)

نطاق وزن العبوة:

3-100 جرام (قابلة للتخصيص)

![]() شهادة:

CE,ISO,SGS

شهادة:

CE,ISO,SGS

خبراء التعبئة والتغليف

يوجد جهاز طرق على القالب للسماح بوضع المادة بشكل كامل

محرك مؤازر يتحكم في سحب الفيلم وإغلاقه

شاشة تحكم ذكية تعمل باللمس للتحكم الذكي PLC

| آلة تعبئة وتعبئة وتغليف عصا ملح الحبيبات السكرية عالية السرعة |

|

نطاق العبوة |

1-100g |

|

طول الكيس |

30-180 مم |

|

عرض الكيس |

20-75 مم |

|

السرعة |

80-130 كيس/دقيقة |

|

أبعاد الماكينة |

790*1050*1600mm(L*W*H) |

|

وزن الماكينة |

300 كجم |

|

مصدر الهواء |

0.6 ميجا باسكال |

|

نوع الختم |

ثلاثة ختم جانبي، ختم خلفي |

|

شكلالقياس |

نظام الكوب الحجمي |

|

مواد التعبئة |

بولي إيثيلين/بولي إيثيلين، ألومنيوم/بولي إيثيلين، ورق/بولي إيثيلين بوليفستر/بولي إيثيلين |

|

المواد |

المواد الغذائية والأدوية والصناعات الكيماوية وصناعة مستحضرات التجميل من جزيئات التعبئة والتغليف الحجمي |

5.خيارات الختم:

يوفر YS-65K عادةً ختمًا حراريًا وتقنيات ختم أخرى لضمان إغلاق الأكياس بشكل صحيح ومحكم الإغلاق، مما يطيل من عمر المنتج.

6.واجهة سهلة الاستخدام:

مزودة بشاشة تعمل باللمس أو لوحة تحكم مماثلة لسهولة التشغيل، مما يسمح للمشغلين بضبط الإعدادات ومراقبة الأداء.

7.التغذية الآلية للمنتج:

أنظمة القادوس التي تقوم بتغذية المنتج تلقائيًا إلى نظام الجرعات، مما يقلل من العمل اليدوي ويزيد من الكفاءة.

8.هيكل من الفولاذ المقاوم للصدأ:

YS-65K مصنوعة بشكل عام من الفولاذ المقاوم للصدأ للحفاظ على معايير النظافة، خاصةً للمنتجات الغذائية.

9.اكتشاف الأخطاء والسلامة:

تتميز الموديلات المتقدمة بأجهزة استشعار وإنذارات للكشف عن القواديس الفارغة ومشكلات الختم وانسداد المنتج، مما يضمن التشغيل السلس وتقليل وقت التوقف عن العمل.

10.صيانة منخفضة:

مصممة بتصميم معياري ومكونات قليلة التآكل، مما يضمن سهولة الصيانة والتنظيف.

محكم الإغلاق:

تكون الأكياس المملوءة محكمة الغلق بالحرارة، مما يضمن إحكام غلقها. كما توفر بعض الماكينات أيضاً خيارات الفتحات المسيلة للدموع لسهولة الفتح.

التقطيع:

تقوم الماكينة YS-65K بتقطيع الأكياس المملوءة والمختومة إلى عبوات فردية أو سلسلة من الأكياس الجاهزة للتوزيع أو التغليف الثانوي.

ترميز الدُفعات والطباعة:

يمكن لبعض الموديلات طباعة أرقام الدُفعات وتواريخ انتهاء الصلاحية والرموز الشريطية على كل كيس لإمكانية التتبع والامتثال للمتطلبات التنظيمية.

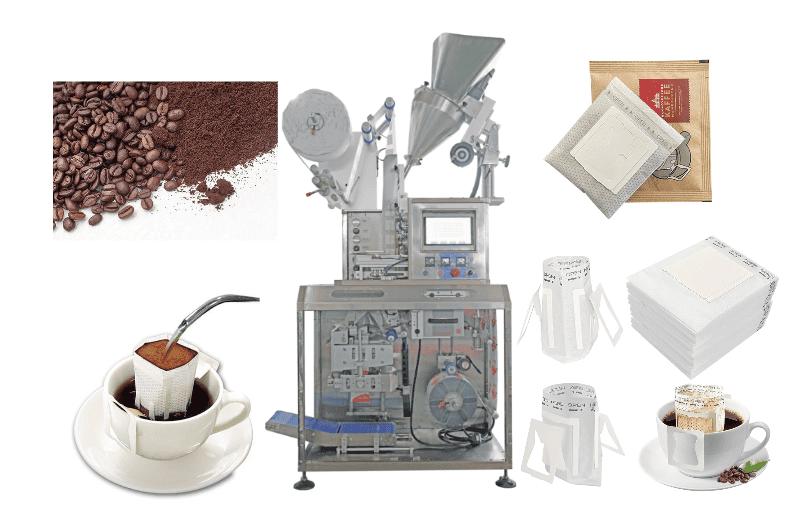

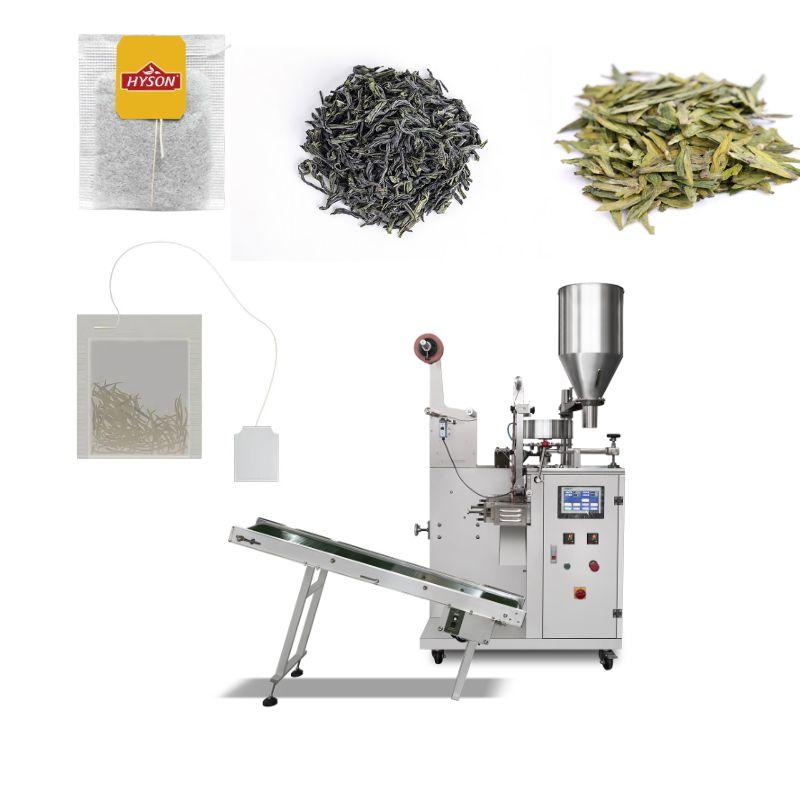

التطبيق: لا يعد YS-188X مناسبًا لتغليف القهوة المقطرة فحسب، بل يمكن استخدامه أيضًا على نطاق واسع في التغ...

نوع الفرن، التعبئة السريعة، التعبئة والتغليف السلس...

(مثل الشاي الأسود، والشاي الأخضر، والشاي المعطر، والشاي السائب، وما إلى ذلك)...