![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-ZF90

Model:

YS-ZF90

![]() Speed:

70-100 bag/min

Speed:

70-100 bag/min

![]() Bag Size:

120mm/140mm/160mm/180mm

Bag Size:

120mm/140mm/160mm/180mm

![]() Pack Weight Range:

1-10g(customizable)

Pack Weight Range:

1-10g(customizable)

![]() Film Material:

Nylon,Polyester Net,Non-woven Fibries,Corn Fiber(Food Grade)

Film Material:

Nylon,Polyester Net,Non-woven Fibries,Corn Fiber(Food Grade)

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Pyramid bag/Rectangular bag

Bag Shape:

Pyramid bag/Rectangular bag

![]() Machine Size:

1000*1000*2260mm

Machine Size:

1000*1000*2260mm

![]() Weight:

410kg

Weight:

410kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

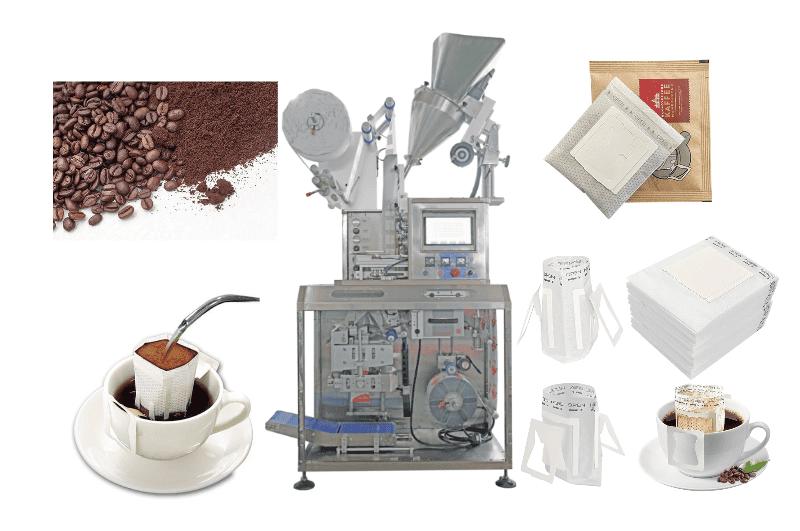

Tea bag sample:

This machine can make pyramid tea bags and rectangular tea bags.

Single-Chamber Tea Bag Machine

Double-Chamber Tea Bag Machine

Pyramid Tea Bag Machine

Envelope Tea Bag Machine

Multi-Lane Tea Bag Machine

Electronic weighing method:

This machine can not only make pyramid tea bags but can also be adjusted into rectangular tea bags. Just click on the touch screen to switch the bag shape.

Electronic Scale System:

The machine uses an Electronic Scale System to package different tea combinations in one bag. The limit is 12 kinds of tea.(If it is tea powder packaging, the feeding device needs to be a screw feeder)

Mixed tea bags can be achieved by placing different tea leaves in different material trays.

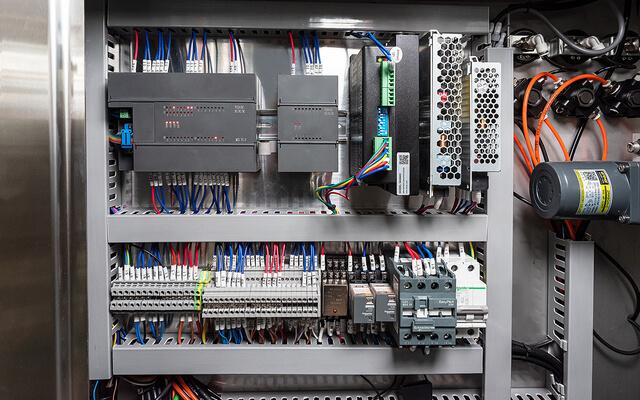

Electrical power system:

Quality brand electric system like Schneider.PLC control system bewith YOUNGSUN with Reliable quality

Touch Screen:

PLC controller and colour touch screen,all parameters can be set onthe control panel.easy to operate.language switchable(Any adjustments that need to be made need to be made on the touch screen.)

If you want to pack tea bags of different sizes, you only need to change the former.(We have a complete operation video. It can easily guide you how to replace the tea bag packaging machine's former)

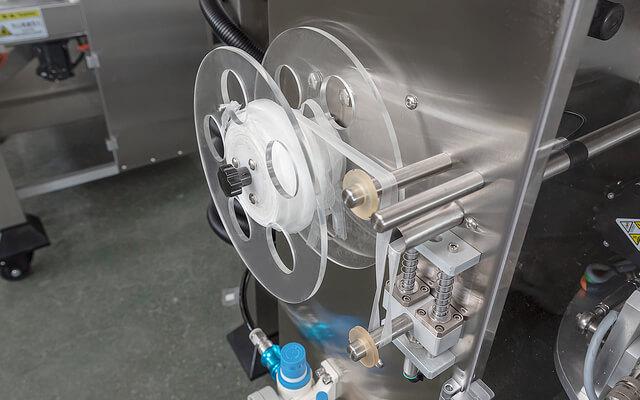

Waste Collection Device:

The remaining film is collected by this device for easy recycling.

Types of Tea Bag Packaging Machines

|

YS-ZF90 High Speed Pyramid Tea Bag Machine |

|

Pack Range |

1-10g |

|

Bag Length |

45-90mm |

|

Bag Width |

40-90mm |

|

Speed |

70-100 bags/min |

|

Machine Dimension(L*W*H) |

1000*1000*2260mm |

|

Machine Weight |

410kg |

|

Power |

AC220V/ 50-60HZ/2KW |

|

Gas Source |

≥0.6Mpa |

|

The Material ofPacking Film |

Nylon,Polyester Net,Non-woven Fibries,Corn Fiber(Food Grade) |

|

Weighting Method |

2-head Electronic Scale/4-head Electronic Scale/6-head Electronic Scale |

Pyramid Bag Formation: YS-ZF90 specifically create pyramid-shaped tea bags, allowing for more space for tea leaves to expand and release flavors.

High-Speed Operation: YS-ZF90 can produce a high number of tea bags per minute, enhancing productivity for manufacturers.

Automatic Operation: Fully automated systems often include features such as automatic feeding, bag forming, filling, sealing, and cutting, reducing the need for manual intervention.

Flexible Filling Options: Machines can accommodate different types of tea leaves, herbs, or blends, and often have the ability to handle various filling weights.

Sealing Technology: Advanced sealing methods (e.g., heat sealing or ultrasonic sealing) ensure that the bags are securely closed, preventing leakage and maintaining freshness.

Quality Control Features: Integrated systems may include inspection mechanisms to check for bag integrity, weight consistency, and fill quality.

User-Friendly Interface: Touchscreen controls and user-friendly interfaces allow for easy operation, monitoring, and adjustments.

Compact Design: Many machines are designed to fit into limited production spaces while still being robust enough for industrial use.

Material Compatibility: These machines can work with various packaging materials, including biodegradable options, catering to sustainability preferences.

Customizable Options: Some machines offer customization options for bag sizes, shapes, and packaging styles, allowing for branding and marketing flexibility.

Integration with Other Equipment: Many pyramid tea bag machines can be integrated with labeling, cartoning, or other packaging equipment for a complete packaging line.

Easy Maintenance: Designs that facilitate easy access for cleaning and maintenance help to reduce downtime and ensure consistent operation.

Application: YS-188X is not only suitable for the packaging of drip coffee, but can also be widely used in the inner and outer bag packaging of other similar products, such as tea, herbal drinks, etc., to ...

The Pyramid tea bag machine has a precise weighing system, ideal for use (such as black tea, green tea, scented tea, loose tea, etc.) and can be used in combination with outer packaging machines and box filli...

All parts in contact with materials are made of foode grade 304slainless steel,easy to clean,2-head rotating hot cutter increases machine efficiencythe speed up to 80bags/min....

The tea bag packaging machine is suitable for crushed tea, loose tea, tea powder or granules, coffee or other small granules, etc....

The Filter Tea Bag with Envelope Packing Machine addresses growing market demands for sanitary, convenient, and quality teaproducts. The added envelope appeals to hygiene-conscious consumers and adds an eleme...

User-Friendly Design The intuitive design of this machine makes it easy for our operators to handle without extensive training.2024-08-09

The pyramid tea bag is beautifully shaped and I am very satisfied. Thanks Ethan2024-08-09

Efficient and Reliable Our tea bag packaging machine has been incredibly efficient and reliable, meeting our production demands effortlessly.2024-08-09

The machine runs very stably, and the ultrasonic bonding speed and stability are very high. I am very satisfied2024-08-09