![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-65K

Model:

YS-65K

![]() Speed:

90-130bag/min

Speed:

90-130bag/min

![]() Bag Size:

Length:30-180mm Width:20-75mm

Bag Size:

Length:30-180mm Width:20-75mm

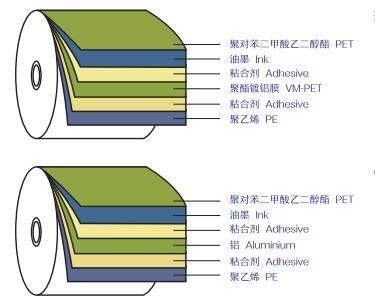

![]() Film The Material:

BOPP/Polyethylene,Aluminium/Polyethyene,Paper/PolyethylenePolyester/Aluminizer/Polyethylene and so on.

Film The Material:

BOPP/Polyethylene,Aluminium/Polyethyene,Paper/PolyethylenePolyester/Aluminizer/Polyethylene and so on.

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

3-100g(customizable)

Pack Weight Range:

3-100g(customizable)

![]() Machine Size:

790*1050*1600mm

Machine Size:

790*1050*1600mm

![]() Machine Weight:

300kg

Machine Weight:

300kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

Sample bag :

Film Material:Polypropylene/Polyethylene, Aluminum Foil/Polyethylene.

Smart touch screen:

Measuring cup feeding:Fast and precise dispensing of materials

VIBRATION PACK FORMER:The vibration pack former can make the material fall faster,the cursorlocator keeps the graphic in the correct position on the bag

A toolbox and some wearing parts will be prepared before delivery

1.There is a knocking device on the former to allow the material to be put in more fully

2.Servo motor controls film drawing and sealing

3.PLC intelligent control touch screen

|

Fully automatic high speed granule packaging machine 90-130bag/min |

|

Pack Range |

1-100g |

|

Bag Length |

30-180mm |

|

Bag Width |

20-75mm |

|

Speed |

80-130 bags/min |

|

Machine Dimension |

790*1050*1600mm(L*W*H) |

|

Machine Weight |

300kg |

|

Air Source |

0.6Mpa |

|

Sealing Type |

Three side seal, back seal |

|

Form OfMeasurement |

Volumetric Cup System |

|

Packing Material |

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/Polyethylene Polvester/Aluminizer/Polvethvlene |

|

Material |

Food, Medicine, Chemical industry, Cosmetics industry of particlesofmeasurement packing |

YS-65K high-speed granule packaging machine is designed to package granular products like grains, seeds, salt, sugar, or small snacks efficiently and accurately. Here’s an overview of the typical features and functions:

YS-65K Granule packaging machine 1.Fast and precise dispensing of materials 2.The vibration pack former can make the material fall faster,the cursorlocator keeps the graphic in the correct position on the...

YS-460K Snacks Potato Chips Packing Machine is suitable , dried fruits and other materials that can be quantitatively weighed....

Yisen machine is suitable for packaging different kinds of pet food, such as dog food, cat strips, pet cans, feed, etc. Stand-up pouch packaging has become extremely popular in the pet food industry; our ...

Yisen manufacturers provide a wide packaging solution of jerky, such as beef jerky, pork jerky, and so on....

80K Back-Sealed Packaging Solution for Dried Chili The 80K packaging machine provides a high-efficiency, precision-based solution for back-sealed packaging of dried chili. Designed to handle deli...