![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-61K

Model:

YS-61K

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

Length:30-170mm Width:30-130

Bag Size:

Length:30-170mm Width:30-130

![]() Film The Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

Film The Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

![]() Gas Source:

electric

Gas Source:

electric

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

1-100g(customizable)

Pack Weight Range:

1-100g(customizable)

![]() Machine Size:

900*1100*1900mm

Machine Size:

900*1100*1900mm

![]() Machine Weight:

300kg

Machine Weight:

300kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

sample:Nuts snacks packing machine it is suitable forpopcorn, shrimp chip, salt, sugar, rice, sunflower seed, peanut, beans, nuts, pistachio, peas, instant oatmeal / cereal oats, etc.

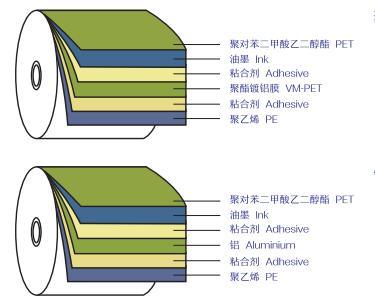

Film Material:Polypropylene/Polyethylene, Aluminum Foil/Polyethylene.

1.Measuring cups Weighing System:The weighing system weighs the material by controlling its volumeIt has high speed and good cost performance.

2.Touch Screen PLC intelligent: control touch screen,Can adjust the temperature, packagesize and package weight

3.Film roll stand: The stepper motor controls the film pulling to make the film roll smoother.

Stepper motor controls film pulling

304 Stainless Steel Silo

PLC intelligent control touch screen

| YS-61K Nuts snacks packing machine |

|

Range ofMeasurement |

3-100g(Depending on product density) |

|

Bag Length |

30-170mm(cancustomize) |

|

Bag Width |

30-130mm(can customize) |

|

Packing Speed |

30-60packs/min |

|

OverallDimension |

900*1100*1900mm |

|

Weight |

400kg |

|

Total Power |

220V/50HZ/1.4KW |

|

Sealing Method |

Three side seal/back seal/four side seal |

YS-61K pouch packing machine for nuts and snacks is specifically designed to handle a variety of small, dry food items efficiently, ensuring freshness, hygiene, and precision. Here’s an overview of its key features and functions:

Automatic Weighing & Dosing: Uses load cells and electronic scales to ensure precise weight in each pouch. This is essential for portion control and compliance with labeling requirements.

Pouch Compatibility: Supports a variety of pouch types (e.g., pre-made bags, stand-up pouches, zipper pouches), allowing versatility in packaging.

Fast Bagging Speed: Advanced models offer high-speed packaging capabilities, with some machines handling 40-80 bags per minute.

User-Friendly Interface: Equipped with a touch screen control panel that allows operators to adjust parameters like pouch size, weight, and speed easily.

Product Sensors: Optical sensors detect the presence and alignment of pouches, preventing wastage by stopping the process if a pouch is not correctly positioned.

Sealing Mechanism: Uses heat sealing, ultrasonic sealing, or zip-lock closures depending on pouch type and material, ensuring airtight sealing to preserve freshness.

Temperature Control: Built-in temperature control systems adjust the heat levels for consistent sealing quality, especially important for different packaging materials.

Quality Assurance: Some machines include metal detectors or x-ray systems to detect contaminants within the nuts or snacks.

Compact Design: Modern machines are compact and often mobile, making them ideal for smaller production spaces and easy to integrate into existing packaging lines.

Dust Collection Systems: Since nuts can create dust, dust collection systems help keep the packaging area clean and reduce maintenance needs.

Product Feeding: The machine's hopper automatically feeds nuts and snacks into the weighing unit for portioning.

Pouch Filling: After weighing, the nuts are dispensed into the pouches, minimizing spillage and reducing waste.

Bag Forming (if applicable): Form-fill-seal machines create pouches from roll stock material, saving on pre-made pouch costs.

Printing & Labeling: Includes date coding and labeling functions, allowing for barcodes, expiry dates, and batch numbers to be printed directly on the pouch.

Sealing & Cutting: Seals each pouch and then cuts it, resulting in individual packages ready for boxing or direct sale.

Error Detection & Alarms: Automatically detects issues like missing pouches, low material, or weight discrepancies and alerts the operator to ensure smooth operation.

Automatic Cleaning Cycle: Some machines have an auto-cleaning function to flush out residual products, which is particularly useful for flavor or product changeovers.

YS-61K Nuts Snacks Packing Machine optimizes packaging speed, maintains high quality, and reduces labor and material waste, making it ideal for nut and snack manufacturers aiming to scale efficiently.

YS-80K snacks granular packing machine is suitable for packaging various granular, flake, strip and shaped materials such as candy, melon seeds, peanuts, nuts, beans, potato chips, popcorn, almonds, dried ...

YS-460K Snacks Potato Chips Packing Machine is suitable , dried fruits and other materials that can be quantitatively weighed....

isen machines can pack food silica gel, synthetic silica gel, new silica gel, and other silica gel agents. The 4-sided seal or 3-sided packaging is extremely popular in the silica gel industry. We can cus...

Yisen manufactures a wide range of packaging machines specifically designed for bagging, wrapping, or container-filling snack foods including packaging chips, crackers, cookies, popcorn, beef jerky, nuts, ...

Yisen machine is suitable for packaging different kinds of pet food, such as dog food, cat strips, pet cans, feed, etc. Stand-up pouch packaging has become extremely popular in the pet food industry; our ...