![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-80K

Model:

YS-80K

![]() Speed:

10-30BAGS/MIN

Speed:

10-30BAGS/MIN

![]() Bag Size:

Length:40-250mm Width:40-200mm

Bag Size:

Length:40-250mm Width:40-200mm

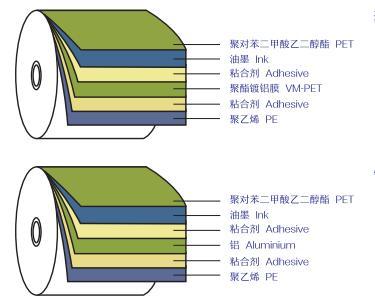

![]() Film The Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

Film The Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

100g-1000g(depends on the material density)

Pack Weight Range:

100g-1000g(depends on the material density)

![]() Machine Size:

970mm*900mm*1900mm

Machine Size:

970mm*900mm*1900mm

![]() Machine Weight:

350kg

Machine Weight:

350kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

Applicable:

rice, corn, pet food, coffee beans, dried fruits, popcorn, sesame, seasonings, tea, washing powder, etc.

Film roll raw materials:

PLC intelligent control touch screen

304 Stainless Steel Silo

Servo motor controls film drawing and sealing

|

Fully automatic Detergent Packing Machine |

|

Packing Range |

100g-1000g(depends on the material density) |

|

Bag Size |

(L):40-250mm (W):40-200mm |

|

Speed |

15-30BAGS /MIN |

|

Dimension(L*W*H) |

970mm*900mm*1900mm |

|

Machine Weight |

350kg |

|

Power |

AC220V150-60HZ11.4KW |

|

Gas Source |

≥0.6Mpa |

|

Bag Type |

Back sealing/Three sides sealing |

|

The Material Of Packing Film |

BOPP/Polvethylene Aluminium/Polvethylene Paper/Polvethylene.Polvester/Aluminizer/Polvethvlene and so or |

YS-80K Automatic Detergent Packing Machine is designed to streamline the packaging process for detergent products. Here are some common features and functions:

High Speed and Efficiency: Capable of packaging large volumes in a short time, enhancing productivity.

Versatile Packaging Options: Can handle various package types such as pouches, sachets, bottles, or cartons.

Precision Filling: Equipped with advanced filling mechanisms that ensure accurate dosage of detergent.

User-Friendly Interface: Often features touch screens or simple controls for easy operation and monitoring.

Adjustable Settings: Allows customization of package size, weight, and filling speed based on product specifications.

Automatic Sealing and Cutting: Integrates sealing and cutting functions to ensure packages are securely closed.

Quality Control Systems: May include sensors and cameras to check for package integrity and proper filling.

Safety Features: Designed with safety protocols, including emergency stops and safety guards to protect operators.

Compact Design: Space-efficient designs suitable for various production environments.

Durable Construction: Made from high-quality materials to withstand the rigors of continuous operation.

Feeding: Automatically feeds detergent into the packaging system.

Measuring and Dispensing: Accurately measures the right amount of detergent for each package.

Filling: Fills the pre-made or formed packages with detergent.

Sealing: Seals the packages to prevent leakage and contamination.

Labeling: Can include a labeling mechanism for product identification and branding.

Batching: Capable of batching products for order fulfillment.

Tracking and Reporting: Some machines have integrated software for tracking production metrics and reporting data.

Cleaning and Maintenance: Designed for easy cleaning and maintenance to ensure hygiene and efficiency.

These features and functions help manufacturers improve their packaging processes, reduce labor costs, and maintain product quality.

YS-65K Granule packaging machine 1.Fast and precise dispensing of materials 2.The vibration pack former can make the material fall faster,the cursorlocator keeps the graphic in the correct position on the...

The 80K granule packaging machine is designed for efficient packaging of granular and flaky materials, and is especially suitable for accurate packaging of condiments such as dried chili peppers. The equip...

Yisen machine is suitable for packaging different kinds of pet food, such as dog food, cat strips, pet cans, feed, etc. Stand-up pouch packaging has become extremely popular in the pet food industry; our ...

Yisen offers an extensive range of fastener packing machines to cater to your various packaging needs, whether you need to pack nails, screws, pins, rivets, or furniture fittings. Our fastener packing mach...

The 61K granule packaging machine provides an efficient and accurate packaging solution for granular products such as Maltesers. The equipment uses an advanced metering system to ensure that the weight of ...