![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-80K

Model:

YS-80K

![]() Speed:

15-30BAGS/MIN

Speed:

15-30BAGS/MIN

![]() Bag Size:

Length:40-250mm Width:40-200mm

Bag Size:

Length:40-250mm Width:40-200mm

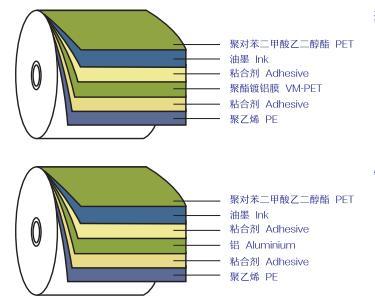

![]() Film The Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

Film The Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

50-1000g

Pack Weight Range:

50-1000g

![]() Machine Size:

970mm*900mm*1900mm

Machine Size:

970mm*900mm*1900mm

![]() Machine Weight:

350kg

Machine Weight:

350kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

Sample:YS-80K snacks packing machine is suitable for packaging various granular, flake, strip and shaped materials such as candy, melon seeds, peanuts, nuts, beans, potato chips, popcorn, almonds, dried fruits and other materials that can be quantitatively weighed.

Film Material:Polypropylene/Polyethylene, Aluminum Foil/Polyethylene.

Ribbon Coder:The production date can be printed on the bag

PLC intelligent control touch screen

304 Stainless Steel Silo

Servo motor controls film drawing and sealing

|

YS-80K snacks packing machine |

|

Packing Range |

100g-1000g(depends on the material density) |

|

Bag Size |

(L):40-250mm (W):40-200mm |

|

Speed |

15-30BAGS /MIN |

|

Dimension(L*W*H) |

970mm*900mm*1900mm |

|

Machine Weight |

350kg |

|

Power |

AC220V150-60HZ11.4KW |

|

Gas Source |

≥0.6Mpa |

|

Bag Type |

Back sealing/Three sides sealing |

|

The Material Of Packing Film |

BOPP/Polvethylene Aluminium/Polvethylene Paper/Polvethylene.Polvester/Aluminizer/Polvethvlene and so or |

Application: YS-SP350 Pet food packaging machine it is suitable for conventional granular zipper bags, standing bags, pre-made bags packing such as nuts, frozen food, dry food, spices, biscuits, beans, oat...

YS-460K Snacks Potato Chips Packing Machine is suitable , dried fruits and other materials that can be quantitatively weighed....

Yisen manufactures a wide range of packing machines, suitable for packaging potato chips. And can be used to pack fragile bulk items. Our machine can also add another nitrogen machine to keep the original...

Yisen manufactures a wide range of packaging machines specifically designed for bagging, wrapping, or container-filling snack foods including packaging chips, crackers, cookies, popcorn, beef jerky, nuts, ...

Yisen packaging machine is suitable for legal cannabis packaging. The type and size of the packaging bag can be selected according to customer requirements. We have delivered packaging solutions to compan...