![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-65F

Model:

YS-65F

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

Length:30-180mm Width:20-140mm

Bag Size:

Length:30-180mm Width:20-140mm

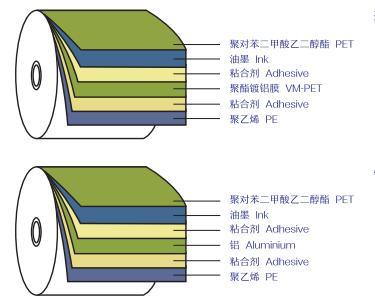

![]() Film The Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

Film The Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

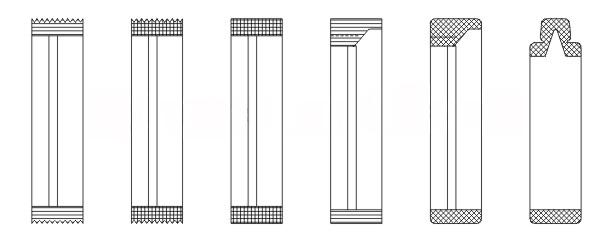

![]() Bag Shape:

The corners can be cut,Back seal, three side seal, four side seal

Bag Shape:

The corners can be cut,Back seal, three side seal, four side seal

![]() Pack Weight Range:

1-100g(customizable)

Pack Weight Range:

1-100g(customizable)

![]() Machine Size:

850 * 1100 * 1900 mm

Machine Size:

850 * 1100 * 1900 mm

![]() Machine Weight:

400kg

Machine Weight:

400kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

Sample:YS-65F Coffee Powde Stick Packaging Machineit is suitable for many kinds of powder products, such as tea powder, medical powder, chemical powder, flour, milk powder, coffee powder, glucose, medical powder, nutrition powder, etc.

Film roll material:BOPP/Polyethylene,Aluminium/Polyethyene,Paper/PolyethylenePolyester/Aluminizer/Polyethylene and so on.

1.Touch Screen:PLC intelligent control touch screen,Can adjust the temperature, packagesize and package weight

2.Beating device:When the material goes into the former, the beater will hit the former athigh speed so that the material can enter the packaging bag more fully

3.Warning light:When a machine fails during operation, an alarm will be sounded

4.Servo Motors:Servo motor controls feeding and sealing, faster and more accurate

5.Air pipe connection: The air pipe is connected to the air compressor to control the clamping and pulling of the bag. The machine pulls the film accurately and the packaging speed is faster. The clamping and pulling

6.Vertical Screw:The vertical screw feeding method effectively reduce material dust andachieve a better sealing effect.

7.Inclined screw:The design of the inclined screw helps prevent material blockage duringfeeding and ensures the continuity of the production process.

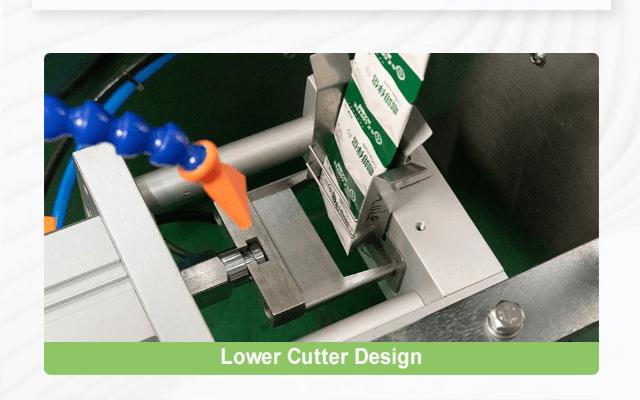

8.Lower Cutter Design:Suitable for different cutting methods such as sawtooth cuttingflat cuttinground corner cuttingspecial-shaped cutting

1. Suitable for the metering and packaging of powdered products in the food, medicine, chemical and cosmetic industries.

2. It can automatically complete bag making, metering, feeding, sealing, slitting, counting, and can be configured with functions such as printing batch numbers according to customer requirements.

3. Touch screen operation, PLC control, driving stepper motor to control bag length, stable performance, easy adjustment, accurate detection. Intelligent temperature controller, PID adjustment, to ensure that the temperature error range is controlled within 1°C

|

YS-65F Coffee Powde Stick Packaging Machine |

|

Measuring range |

1 -100 g (3-100 ml) |

|

Bag size |

Length (L): 30-180 mm Width (W): 20-140 mm |

|

Packing speed |

30 - 60 bags/min |

|

Dimensions |

850 * 1100 * 1900 mm |

|

Machine weight |

400 kg |

|

Total power |

220V/50Hz/1.4kw |

YS-65F coffee powder stick packaging machine is specialized equipment used for filling coffee powder into stick-shaped sachets or pouches, sealing them, and preparing them for sale or distribution.

YS-61F Vertical powder flour packaging machine Suitable for packaging flour, cocoa powder, protein powder, seasoning powder, Chinese medicine powder, and washing powder...

MY-KBQ100 Powder packaging machine Application: Suitable for metering and packaging of powdered products in the food, medicine, chemical and cosmetic industries....

Yisen packaging machine has a great advantage in packaging flour. It is a leading manufacturer. As long as you have demand, we will customize the best packaging solution for you. Our flour packaging scheme i...

Yisen Manufacturing has many experiences in packaging milk powder, and we will provide customers with a solution that suits them. Packing with jars is the most common packaging method in the milk powder indu...

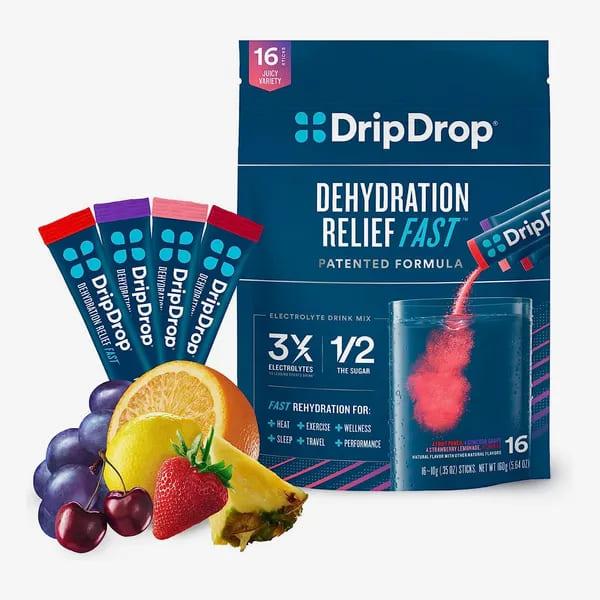

The 65F powder packaging machine provides an efficient and precise packaging solution for electrolyte powder. The machine is equipped with an advanced metering system to ensure that the weight of each package...

User-Friendly Interface "The interface is so intuitive; even our new staff learned to operate it within minutes. Saves us a lot of training time!"2024-08-20

Efficient and Reliable "This machine has made our spice packing process incredibly efficient. It's reliable2024-08-20

Precision Packing "Impressed with its accuracy! Every packet is consistently filled to the exact weight we need. No more wastage2024-08-20

"Uses less energy than expected. Helps keep our operational costs down without sacrificing performance2024-08-20