![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-80K

Model:

YS-80K

![]() Speed:

15-30BAGS/MIN

Speed:

15-30BAGS/MIN

![]() Bag Size:

Length:40-250mm Width:40-200mm

Bag Size:

Length:40-250mm Width:40-200mm

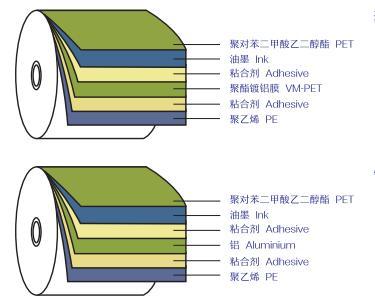

![]() Film The Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

Film The Material:

PE composite film, such as: pure aluminum, aluminumplating and other prefabricated bags

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

1-1000g(customizable)

Pack Weight Range:

1-1000g(customizable)

![]() Machine Size:

970mm*900mm*1900mm

Machine Size:

970mm*900mm*1900mm

![]() Machine Weight:

350kg

Machine Weight:

350kg

![]() Certification:

Certification:

YS-80K Detergent powder packing machine Apply to pack bulk grain, slice, short bar material products such as whole grain, oatmeal, cereal oats, puffy food, popcorn, shrimp chip, salt, sugar, rice, sunflower seed, peanut, beans, nuts, pistachio, peas, etc.

Raw material:

Touch Screen PLC: intelligent control touch screen,Can adjust the temperature, packagesize and package weight

Barrel High capacity barrel 304 stainless steel

Film Roll Installation Device:Consists of multiple film-penetrating shafts,the film is pulled moresmoothly and stably,and the bag is smoother and beautiful

PLC intelligent control touch screen

304 Stainless Steel Silo

Servo motor controls film drawing and sealing

| YS-80K Detergent powder packing machine |

|

Packing Range |

100g-1000g(depends on the material density) |

|

Bag Size |

(L):40-250mm (W):40-200mm |

|

Speed |

15-30BAGS /MIN |

|

Dimension(L*W*H) |

970mm*900mm*1900mm |

|

Machine Weight |

350kg |

|

Power |

AC220V150-60HZ11.4KW |

|

Gas Source |

≥0.6Mpa |

|

Bag Type |

Back sealing/Three sides sealing |

|

The Material Of Packing Film |

BOPP/Polvethylene Aluminium/Polvethylene Paper/Polvethylene.Polvester/Aluminizer/Polvethvlene and so or |

Automatic Operation: YS-80K operate automatically, reducing the need for manual intervention, which increases efficiency.

Versatile Packaging Sizes: YS-80K can typically handle various pouch sizes and styles (e.g., stand-up pouches, flat pouches).

High-Speed Production: Many models are capable of high-speed packaging, allowing for the processing of large volumes in a short time.

Accurate Weighing: Integrated weighing systems ensure precise filling, minimizing product waste and ensuring compliance with packaging standards.

Sealing Mechanism: Advanced sealing technology (like heat sealing or ultrasonic sealing) ensures that pouches are securely sealed to prevent leakage and maintain product freshness.

User-Friendly Controls: Most machines come with touch screen interfaces and programmable settings for easy operation and monitoring.

Material Compatibility: They can work with various pouch materials, such as polyethylene, polypropylene, or laminated films.

Safety Features: Safety mechanisms such as emergency stops, guards, and alarms to protect operators and prevent accidents.

Maintenance Accessibility: Designed for easy cleaning and maintenance to minimize downtime and ensure hygiene.

Compact Design: Many machines are designed to occupy minimal floor space, making them suitable for various production environments.

Pouch Formation: The machine forms pouches from flat rolls of film, creating the desired shape and size.

Filling: The machine accurately fills the pouches with a predetermined amount of washing powder.

Sealing: After filling, the machine seals the pouches to ensure they are airtight and tamper-proof.

Printing/Labeling: Some machines include options for printing expiration dates, batch numbers, or product information directly on the pouches.

Quality Control: Integrated systems may check for proper fill levels and seal integrity to ensure product quality.

Batch Processing: Capable of handling multiple batches and adjusting to different product types with minimal setup changes.

Integration with Other Systems: Can be integrated with upstream processes (like mixing) and downstream processes (like palletizing) for a complete production line solution.

Remote Monitoring: Some modern machines offer IoT capabilities for remote monitoring and data collection, allowing for efficient production management.

YS-65F Matcha powder packaging machine is suitable for many kinds of powder products, such as tea powder, medical powder, chemical powder, flour, milk powder, coffee powder, glucose, medical powder, nutrition...

YS-80K Detergent powder packing machine Apply to pack bulk grain, slice, short bar material products such as whole grain, oatmeal, cereal oats, puffy food, popcorn, shrimp chip, salt, sugar, rice, sunflower s...

The 65F powder packaging machine provides an efficient and precise packaging solution for electrolyte powder. The machine is equipped with an advanced metering system to ensure that the weight of each package...

Yisen Manufacturing has many experiences in packaging milk powder, and we will provide customers with a solution that suits them. Packing with jars is the most common packaging method in the milk powder indu...

Yisen packaging machines can be used in various products, including daily chemical products such as washing powder. Our models are complete, so that customers have a variety of choices, and we can customize ...

Quiet Operation "Surprisingly quiet during operation. Doesn't disrupt our workspace like other machines we've used."2024-08-20

Precision Packing "Impressed with its accuracy! Every packet is consistently filled to the exact weight we need. No more wastage2024-08-20

User-Friendly Interface "The interface is so intuitive; even our new staff learned to operate it within minutes. Saves us a lot of training time!"2024-08-20

Efficient and Reliable "This machine has made our spice packing process incredibly efficient. It's reliable2024-08-20