![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-61K

Model:

YS-61K

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

Length:30-170mm Width:30-130

Bag Size:

Length:30-170mm Width:30-130

![]() Film Material:

BOPP/Polyethylene,Aluminium/Polyethyene,Paper/PolyethylenePolyester/Aluminizer/Polyethylene and so on.

Film Material:

BOPP/Polyethylene,Aluminium/Polyethyene,Paper/PolyethylenePolyester/Aluminizer/Polyethylene and so on.

![]() Gas Source:

electric

Gas Source:

electric

![]() Bag Shape:

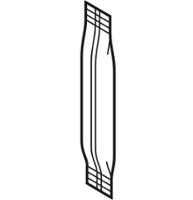

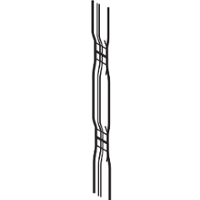

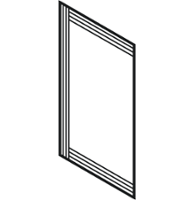

Back seal, three side seal, four side seal

Bag Shape:

Back seal, three side seal, four side seal

![]() Pack Weight Range:

3-100g(customizable)

Pack Weight Range:

3-100g(customizable)

![]() Machine Size:

900*1100*1900mm

Machine Size:

900*1100*1900mm

![]() Machine Weight:

400kg

Machine Weight:

400kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

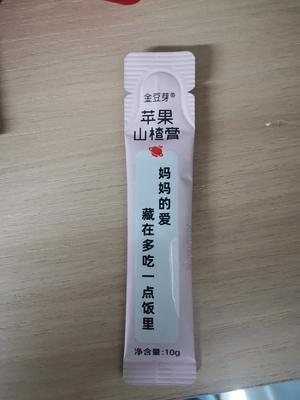

Application:fine granule sugar salt stick filling sealing machine suitable for kinds of loose granule products such as sugar, salt, small grains, seeds, spice, sesame, seasoning, coffee, etc.

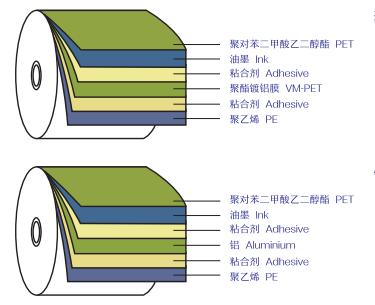

Film Material:Polypropylene/Polyethylene, Aluminum Foil/Polyethylene.

Packing bag shape:Four-side seal, three-side seal, back seal, continuous bag, stick packs

Ribbon Coder:The production date can be printed on the bag

Forming machine:The width of the bag is determined by the former. If you want to produce different bag widths on one machine, you need to change the former. The length of the bag can be set directly on the touch screen.

Film rack:The roll film can be fed into the former smoothly.

Stepper motor controls film pulling

304 Stainless Steel Silo

PLC intelligent control touch screen

|

Automatic sugar bag packaging machine stick bag packaging machine |

|

Range ofMeasurement |

3-100g(Depending on product density) |

|

Bag Length |

30-170mm(cancustomize) |

|

Bag Width |

30-130mm(can customize) |

|

Packing Speed |

30-60packs/min |

|

OverallDimension |

900*1100*1900mm |

|

Weight |

400kg |

|

Total Power |

220V/50HZ/1.4KW |

|

Sealing Method |

Three side seal/back seal/four side seal |

Suitable for instant noodle industry soup bag, desiccant, powder, broken tea and other small granular items packaging Suitable for instant noodle industry soup bag, desiccant, powder,...

YS-85K black pepper Sachet packing machine The machine is suitable for the measurement and packaging of particles, powders, liquids and sauces in food...

YS-65F powder stick bag Packing machine is suitable for many kinds of powder products, such as tea powder, medical powder, chemical powder, flour, milk powder, coffee powder, glucose, medical powder, nutri...

All these powders and the other types of powders can be packed in a Stick pack, Flat 4 Side Seal Sachet ,Doypack with different weight range according to the customer need. ...

Application: Sutable for granule : salt, sugar, washing powder, spice, aginomoto etc. Packing Exambers: ...

The guidance and debugging is very convenient, the machine is very stable, the after-sales service is professional and patient, and the packaging effect is good2024-08-09

User-Friendly Design "The intuitive design makes operating this sauce packaging machine a breeze. Our staff learned to use it quickly without any issues.2024-08-09

Compact and Space-Saving "Perfect for our limited space, this machine's compact size doesn't compromise on performance. It fits seamlessly into our production line.2024-08-09

High Quality Output "We've noticed a consistent quality in our sauce packaging since using this machine. It delivers perfectly sealed packets every time.2024-08-09