![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-ZF90

Model:

YS-ZF90

![]() Speed:

70-100 bag/min

Speed:

70-100 bag/min

![]() Bag Size:

120mm/140mm/160mm/180mm

Bag Size:

120mm/140mm/160mm/180mm

![]() Pack Weight Range:

1-10g

Pack Weight Range:

1-10g

![]() Film Material:

Nylon,Polyester Net,Non-woven Fibries,Corn Fiber(Food Grade)

Film Material:

Nylon,Polyester Net,Non-woven Fibries,Corn Fiber(Food Grade)

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

Pyramid bag/Rectangular bag

Bag Shape:

Pyramid bag/Rectangular bag

![]() Machine Size:

1000*1000*2260mm

Machine Size:

1000*1000*2260mm

![]() Weight:

410kg

Weight:

410kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

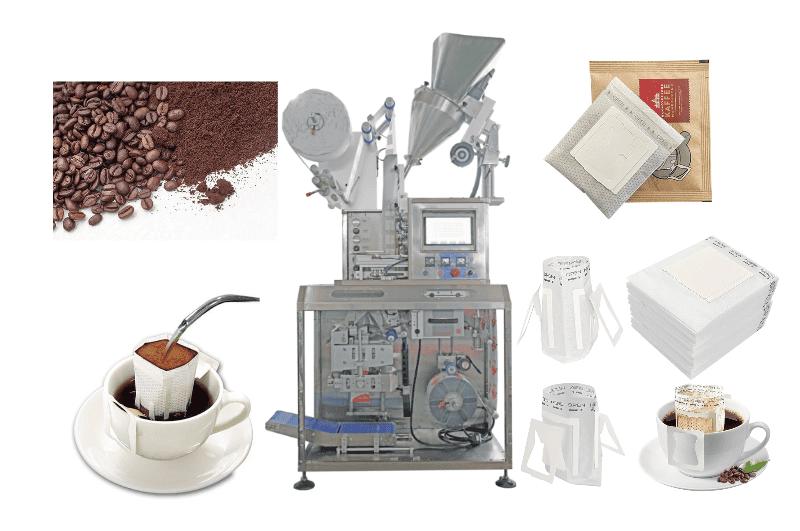

YS-ZF90 The Pyramid tea bag machine has a precise weighing system, ideal for use (such as black tea, green tea, scented tea, loose tea, etc.) and can be used in combination with outer packaging machines and box filling machines

| YS-ZF90 Green tea and black tea packaging machine |

|

Pack Range |

1-10g |

|

Bag Length |

45-90mm |

|

Bag Width |

40-90mm |

|

Speed |

70-100 bags/min |

|

Machine Dimension(L*W*H) |

1000*1000*2260mm |

|

Machine Weight |

410kg |

|

Power |

AC220V/ 50-60HZ/2KW |

|

Gas Source |

≥0.6Mpa |

|

The Material ofPacking Film |

Nylon,Polyester Net,Non-woven Fibries,Corn Fiber(Food Grade) |

|

Weighting Method |

2-head Electronic Scale/4-head Electronic Scale/6-head Electronic Scale |

YS-ZF90 Tea Packaging machines for green tea and black tea offer features designed to preserve quality, enhance production efficiency, and accommodate different packaging styles. Here’s a breakdown of the key features and functions commonly found in these machines:

These packaging machines are designed to meet the specific needs of tea producers, ensuring efficiency, quality preservation, and flexibility in packaging choices.

YS-ZF90 The Pyramid tea bag machine has a precise weighing system, ideal for use (such as black tea, green tea, scented tea, loose tea, etc.) and can be used in combination with outer packaging machines and b...

YS-66 is suitable for packaging green tea, broken tea, black tea, etc....

Application: YS-188X is not only suitable for the packaging of drip coffee, but can also be widely used in the inner and outer bag packaging of other similar products, such as tea, herbal drinks, etc., to ...

YS-188X drip coffee packaging machine is an efficient, fully automated drip coffee packaging machine designed to meet the needs of the modern coffee market. The equipment can not only accurately produce drip ...

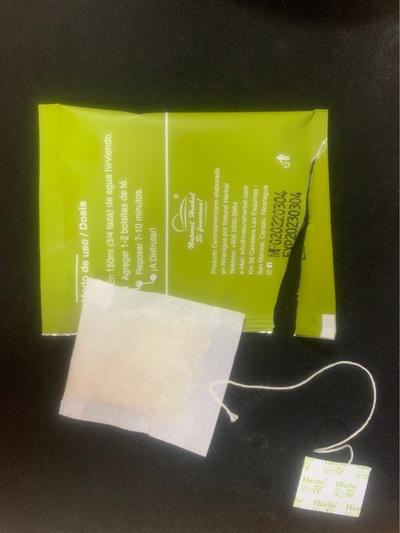

The Filter Tea Bag with Envelope Packing Machine addresses growing market demands for sanitary, convenient, and quality teaproducts. The added envelope appeals to hygiene-conscious consumers and adds an eleme...

The machine runs very stably, and the ultrasonic bonding speed and stability are very high. I am very satisfied2024-08-09

The pyramid tea bag is beautifully shaped and I am very satisfied. Thanks Ethan2024-08-09

Cost-Effective Solution Investing in this machine has proven to be a cost-effective solution for scaling our tea production operations.2024-08-09

Efficient and Reliable Our tea bag packaging machine has been incredibly efficient and reliable, meeting our production demands effortlessly.2024-08-09