![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-40

Model:

YS-40

![]() Speed:

30-100BAGS/MIN

Speed:

30-100BAGS/MIN

![]() Bag Size:

Length:30-120mm Width:13-80mm

Bag Size:

Length:30-120mm Width:13-80mm

![]() Pack Weight Range:

1-40g

Pack Weight Range:

1-40g

![]() Film Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

Film Material:

BOPP/Polyethylene,Aluminium/Polyethylene, Paper/PolyethylenePolvester/Aluminizer/Polvethvlene,filter paper

![]() Gas Source:

electric

Gas Source:

electric

![]() Bag Shape:

Back seal, three side seal

Bag Shape:

Back seal, three side seal

![]() Machine Size:

900*750*1750mm

Machine Size:

900*750*1750mm

![]() Weight:

260kg

Weight:

260kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

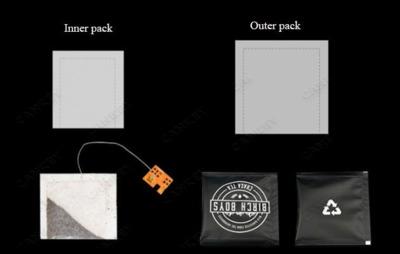

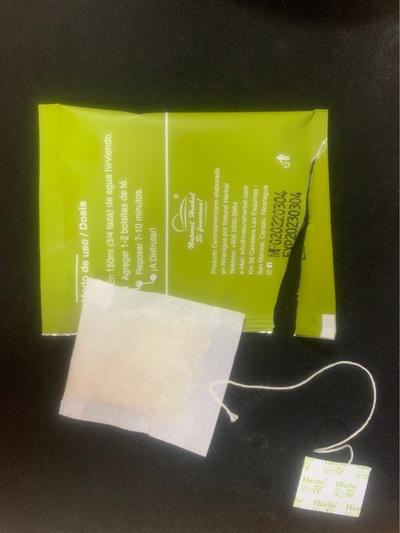

Snus Tea bag packaging machine bag sample:

Bag Type:Back seal

Customize snuff bags of different sizes according to customer needs

Before asking for a quote, you can measure the length, width and weight of the sample on hand. In this way, we can quickly give you a solution.

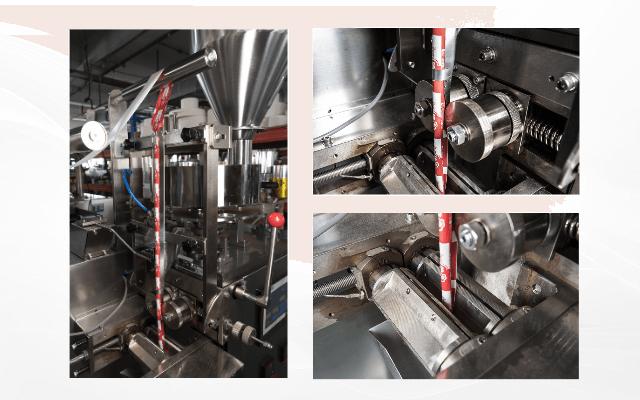

Touch Screen:PLC controller and colour touch screen,all parameters can be set on the control panel,easy to operate,language switchable

Bag Former:Smaller formers designed specifically for snus

Automatic Pick & Place bag infeed

Multi-Language HMl304 stainless steel frame

|

YS-40 Snus Packaging Machine |

| pack range | 1-40g |

|

bag size |

Length:30-110mm Width:13-80mm |

| Speed |

30-100Bags/min |

|

Machine Dimension |

900*750*1750mm |

|

Machine Weight |

260kg |

|

Power |

AC220V150-60HZ/1.5KW |

|

The Material ofInner Bag |

Composite membrane,Tea bag filter paper |

|

Weighting Method |

Measruing Cups,Screw |

YS-40 snus tea bag packaging machine typically comes with a variety of features and functions to ensure efficient and effective packaging. Here are some common ones:

Snus nicotine pouch machine Suitable for small particle packaging such as snuff, broken tea, desiccant, etc....

YS-66 is suitable for packaging green tea, broken tea, black tea, etc....

The Pyramid tea bag machine has a precise weighing system, ideal for use (such as black tea, green tea, scented tea, loose tea, etc.) and can be used in combination with outer packaging machines and box filli...

YS-188X drip coffee packaging machine is an efficient, fully automated drip coffee packaging machine designed to meet the needs of the modern coffee market. The equipment can not only accurately produce drip ...

First pack the inner bag, and then put the inner bag into the outer bag....

The machine runs very stably, and the ultrasonic bonding speed and stability are very high. I am very satisfied2024-08-09

The inner and outer bags are packed perfectly.2024-08-09

User-Friendly Design The intuitive design of this machine makes it easy for our operators to handle without extensive training.2024-08-09

Cost-Effective Solution Investing in this machine has proven to be a cost-effective solution for scaling our tea production operations.2024-08-09