Author:YISEN Pouch Packing Machine Manufacturer TIME:2025-02-28

To maintain a smooth and efficient production process, daily cleaning is crucial. Residue buildup can lead to operational issues, contamination, and product inconsistencies. Follow these steps for routine maintenance:

1.1 Disconnect and Safety First

Always disconnect the machine from its power source before beginning any cleaning process. This ensures both operator safety and prevents accidental machine startup during cleaning.

1.2 Remove Visible Powder Residues

Use soft brushes and lint-free cloths to wipe down surfaces such as belts, conveyors, and machine casings. Pay close attention to areas where powder can accumulate, such as filling nozzles and hoppers.

1.3 Vacuum Hard-to-Reach Areas

Use a vacuum cleaner equipped with fine particle filters to clean areas that are difficult to access, preventing dust from spreading to other parts of the facility.

While daily cleaning focuses on surface maintenance, weekly inspections address potential wear and tear that can affect machine performance.

2.1 Check for Wear and Tear

Inspect all seals, gaskets, and bearings for signs of damage or leakage. Look for any broken or worn parts that could cause malfunctions during production.

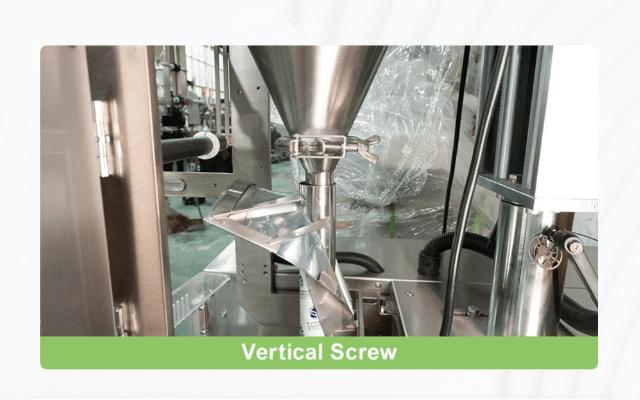

2.2 Lubricate Moving Parts

Lubricate key moving components, such as conveyor belts, augers, and motors, using food-grade lubricants as specified by the manufacturer. This reduces friction and ensures smooth machine operation.

2.3 Replace Worn Parts

Promptly replace any damaged components. This helps avoid unexpected breakdowns and ensures continuous production without delays.

Over time, stubborn powder residues can build up in hard-to-clean areas. To maintain optimal performance, deep cleaning should be conducted periodically.

3.1 Schedule Regular Deep Cleanings

Plan a deep cleaning session every 1-3 months, depending on the machine's usage and production volumes. This will ensure that residue buildup does not compromise machine performance.

3.2 Disassemble Key Components for Thorough Cleaning

Disassemble critical components such as hoppers, chutes, and filling heads. Use soft brushes or high-pressure water jets to scrub away stubborn residues. Always refer to the manufacturer’s guidelines on the correct cleaning agents to use.

3.3 Dry All Parts Completely

After cleaning, allow all components to air dry thoroughly before reassembling the machine. Moisture left behind could lead to corrosion or affect the machine’s performance.

Accurate calibration is crucial for ensuring that the powder packaging machine delivers consistent and precise results. Improper calibration can lead to overfilling or underfilling, both of which impact product quality and waste.

4.1 Calibrate the Machine Regularly

Test the machine's filling accuracy with calibrated weights or test powders. Adjust settings such as filling volumes, sealing temperatures, and conveyor speeds to align with product specifications.

4.2 Record Calibration Results

Document all calibration procedures and results for reference. Regular documentation ensures that any discrepancies can be traced, providing insights into the machine's performance over time.

Proper training of operators is essential not only for machine efficiency but also for safety. Operators must be well-versed in safe operating procedures and emergency protocols.

5.1 Provide Comprehensive Training

Ensure that operators are trained in the proper cleaning protocols, machine operation, and safety measures. This reduces the risk of accidents and ensures that the machine runs efficiently.

5.2 Use Personal Protective Equipment (PPE)

Operators should wear appropriate PPE, including gloves, safety glasses, and masks, to minimize exposure to powders and cleaning chemicals. This protects their health and ensures they can work safely.

5.3 Implement Safety Procedures

Instruct operators on proper lockout/tagout procedures to prevent accidental machine startups during cleaning or maintenance.

Regular maintenance and cleaning are the foundation of a well-functioning powder packaging machine. By following daily, weekly, and deep cleaning practices, calibrating the machine regularly, and training operators effectively, manufacturers can ensure the longevity, efficiency, and consistency of their machines. Keeping your powder packaging machine in optimal condition leads to reduced downtime, improved product quality, and enhanced operational efficiency.