![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-66

Model:

YS-66

![]() Speed:

10-40bags/min

Speed:

10-40bags/min

![]() Bag Size:

∅40-70mm

Bag Size:

∅40-70mm

![]() Pack Weight Range:

1-10g

Pack Weight Range:

1-10g

![]() Film Material:

Tea filter paper and so on

Film Material:

Tea filter paper and so on

![]() Gas Source:

≥0.6Mpa

Gas Source:

≥0.6Mpa

![]() Bag Shape:

round

Bag Shape:

round

![]() Machine Size:

1160*850*1740 mm

Machine Size:

1160*850*1740 mm

![]() Weight:

300 kg

Weight:

300 kg

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

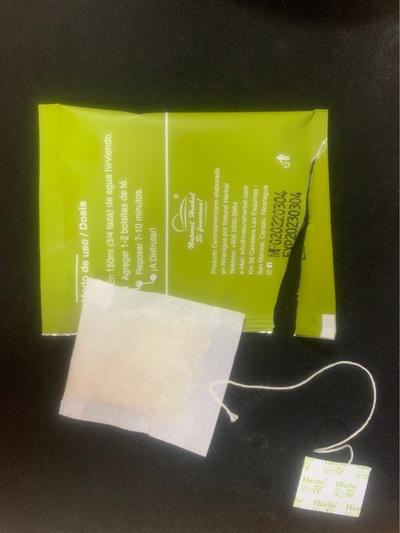

YS-66 Round tea packaging machine is suitable for packaging green tea, broken tea, black tea, etc.

YS-66 tea packaging machine is suitable for particles material such as:tea coffee food,medicine and chemical products.

All the works of bag making measuring filing sealing cutting and counting can be done automatically

The touch screen operation PLC control, drive stepper motor to control the bag length.stable performance,easy to adjust and accurate detection

Packing material: Tea filter paper and so on.

|

YS-66 Round tea packaging machine |

|

Measuring Scope |

1-5g |

|

Bag Size |

∅40-70mm |

|

Packing Speed |

10-40bags/min |

|

Dimension |

1160*850*1740 mm |

|

Weight |

300kg |

|

Total Power |

AC220V/50-60Hz/1.6kw |

|

Gas source |

≥0.6Mpa |

YS-66 round tea packaging machine is designed for efficiently packing loose-leaf tea or tea powder into round-shaped bags or containers. Here are some common features and functions of such machines:

These machines help streamline tea packaging, improve production quality, and reduce the labor and time required for manual packing.

The Pyramid tea bag machine has a precise weighing system, ideal for use (such as black tea, green tea, scented tea, loose tea, etc.) and can be used in combination with outer packaging machines and box filli...

All parts in contact with materials are made of foode grade 304slainless steel,easy to clean,2-head rotating hot cutter increases machine efficiencythe speed up to 80bags/min....

YS-66 is suitable for packaging green tea, broken tea, black tea, etc....

The pyramid tea bag is beautifully shaped and I am very satisfied. Thanks Ethan2024-08-09

User-Friendly Design The intuitive design of this machine makes it easy for our operators to handle without extensive training.2024-08-09

The inner and outer bags are packed perfectly.2024-08-09

Cost-Effective Solution Investing in this machine has proven to be a cost-effective solution for scaling our tea production operations.2024-08-09