Author:YISEN Pouch Packing Machine Manufacturer TIME:2025-02-28

When selecting a Doypack packing machine, it's essential to evaluate various factors to ensure that the machine suits your specific packaging requirements. Whether you're in the food, beverage, or consumer goods industry, the right machine will help enhance efficiency and ensure the quality of your packaged products. This guide will walk you through the primary considerations to keep in mind when choosing a Doypack packing machine.

Understanding your product and packaging needs is the first step when selecting a Doypack packing machine. You need to consider several factors:

By aligning your product specifications with the right machine features, you can ensure smooth packaging processes.

Production capacity is a key consideration when selecting a Doypack packing machine. The machine’s speed should match your production volume requirements:

It's essential to evaluate your current production needs and project future growth to select a machine that will remain efficient as your business expands.

A versatile Doypack packing machine offers flexibility in packaging materials, which is particularly valuable if your product lineup changes over time or if you plan to introduce new packaging innovations.

By choosing a machine with flexible capabilities, you ensure that your operations remain adaptable to market trends and evolving consumer preferences.

In today's competitive landscape, advanced automation technology can significantly enhance the efficiency of your packaging line. Doypack packing machines come with varying levels of automation:

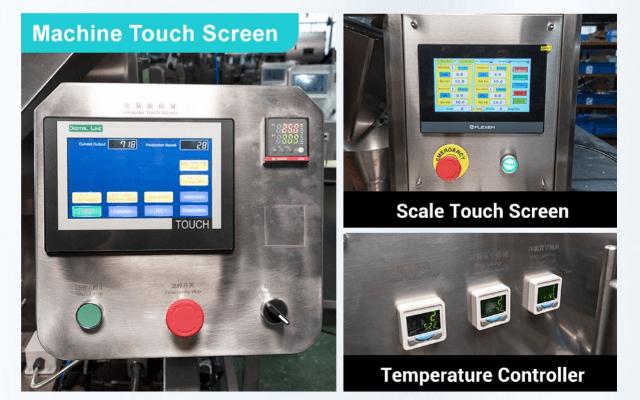

Additionally, look for machines that offer user-friendly interfaces, such as touchscreen controls, and programmable logic controllers (PLCs) for precise operations. These features not only make the machine easier to use but also reduce downtime and facilitate quick troubleshooting.

When investing in a Doypack packing machine, reliability and quality are non-negotiable. A durable machine ensures consistent performance and minimizes downtime. Factors to consider include:

Reviewing testimonials, warranty policies, and machine performance records can also give you a better understanding of how well the machine holds up over time.

Finally, cost plays a significant role in your decision-making process. Consider the total cost of ownership:

Weighing these factors will help you determine whether the machine offers value for money and a strong ROI.

Selecting the right Doypack packing machine involves a comprehensive evaluation of your packaging needs, production capacity, material flexibility, automation requirements, machine reliability, and overall costs. By carefully considering these factors, you can choose a machine that will not only meet your current packaging needs but also support your growth and operational efficiency.

If you’re unsure which machine is the best fit for your business, reach out to a packaging expert for a personalized consultation.