Author:YISEN Pouch Packing Machine Manufacturer TIME:2025-02-28

Snus, a moist tobacco product that originated in Sweden, has experienced a surge in popularity globally. With this rise in demand, the role of packing machines in the production process has become more critical than ever. Snus packing machines are essential for ensuring efficiency, consistency, and compliance with regulatory standards. This article takes a closer look at how snus packing machines have evolved, highlighting key technological advancements that have shaped the industry.

2.1 Manual Systems in the Early Days

In the beginning, snus packing machines were simple and primarily manual. Early machines used mechanical components to portion and pack snus into pouches or containers. These rudimentary machines were designed for reliability, as manufacturers aimed to meet the growing demand while maintaining product quality. The emphasis was on basic functions, with a minimal focus on automation or advanced features.

2.2 Challenges and Limitations

During this phase, the lack of automation led to slower production rates and the potential for human error. This placed a strain on manufacturers to keep up with increasing demand. As the market for snus expanded, the limitations of manual systems became more apparent, pushing the industry toward more advanced technologies.

3.1 Advancements in Technology During the Late 20th Century

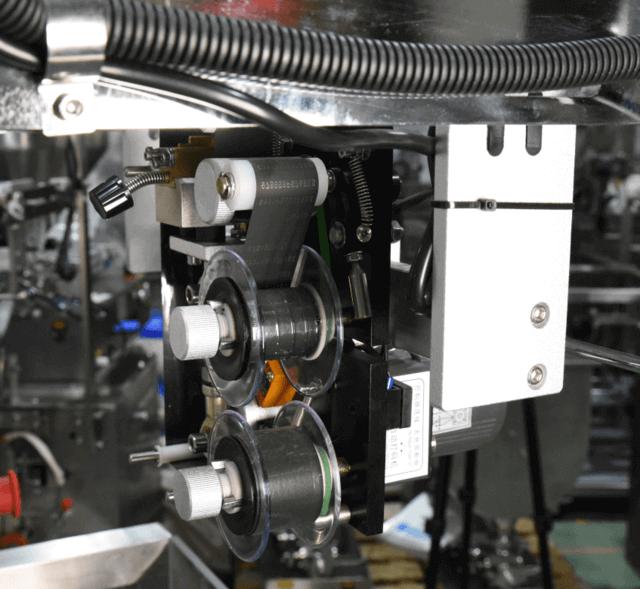

With the advent of automation and precision engineering in the late 20th century, snus packing machines underwent a significant transformation. Automated systems replaced manual labor, allowing for faster, more efficient production. These machines introduced computer-controlled systems, which provided a higher degree of accuracy in measuring and packing snus. The result was consistent product weight and quality, crucial for meeting consumer expectations.

3.2 Cost-Effective Solutions

Automation also brought significant cost reductions. With fewer manual laborers required, production costs dropped, and manufacturers were able to scale their operations more effectively. The precision of these machines also minimized waste, making the entire process more cost-effective and environmentally friendly.

4.1 Advancements in Packaging Materials

The development of new materials has played a key role in enhancing the performance of snus packing machines. Modern packaging materials are designed to retain moisture and preserve the flavor of snus for extended periods. This innovation is crucial for maintaining the quality of snus products during transportation and storage.

4.2 Consumer-Focused Design Enhancements

Alongside material innovations, packaging designs have evolved to cater to consumer convenience. Today’s snus packaging includes ergonomic features that enhance portability and ease of use. Whether for a casual consumer or a frequent user, these design improvements have made snus products more appealing to a wider audience.

5.1 Meeting Health and Safety Standards

As tobacco regulations become more stringent globally, snus packing machines have adapted to meet these requirements. Many modern machines include features that ensure hygiene and traceability, vital for maintaining compliance with health and safety standards. These machines often feature automated cleaning systems to prevent contamination and maintain the integrity of the product.

5.2 Ensuring Quality Control

In addition to hygiene, snus packing machines are equipped with quality control systems to monitor the production process in real-time. These features help ensure that each package meets the required specifications, from weight to packaging integrity, and ultimately ensure product consistency and consumer safety.

6.1 The Power of IoT Connectivity

The next frontier in snus packing machine technology is the integration of Industry 4.0, particularly through IoT (Internet of Things) connectivity. Real-time monitoring allows manufacturers to track production metrics continuously, ensuring that each machine is operating at optimal efficiency. IoT-enabled machines can also provide data that helps in predictive maintenance, preventing unplanned downtime and reducing repair costs.

6.2 The Role of Artificial Intelligence

Artificial intelligence (AI) and machine learning are being used to optimize packing processes. These technologies can predict patterns, optimize workflows, and even suggest improvements based on historical data. As a result, packing machines become not just tools, but smart systems that continuously improve over time.

7.1 The Push Toward Sustainable Materials

As the world becomes more environmentally conscious, the snus industry is shifting toward more sustainable practices. Manufacturers are exploring biodegradable materials and eco-friendly packaging options that reduce the environmental impact of snus packaging. This shift is in response to consumer demand for more environmentally responsible products.

7.2 Reducing Carbon Footprint and Energy Consumption

Snus packing machines are also incorporating energy-efficient designs to minimize their carbon footprint. Through the use of less energy-intensive materials and processes, these machines help reduce the overall environmental impact of snus production. Furthermore, recycling initiatives are being implemented to ensure that waste is minimized throughout the production lifecycle.

The evolution of snus packing machines reflects the growth and sophistication of the snus industry itself. From manual systems to automated precision engineering and smart technologies like IoT and AI, packing machines have adapted to meet the challenges of a rapidly changing market. As the industry moves forward, the focus will continue to be on improving efficiency, ensuring product quality, and adopting sustainable practices. Snus packing machines will remain a critical component in ensuring that the snus industry meets the needs of consumers while complying with regulatory requirements.