1. Gravity Feed Systems. 2. Vibratory Feed Systems. 3. Belt Feed Systems. 4. Auger Feed Systems. 5. Combination Feed Systems. Conclusion....

1. Types of Potato Chips Packaging Machines. 2. Packaging Considerations. 3. Automation and Efficiency. 4. Hygiene and Maintenance. 5. Cost Considerations. Conclusion....

1. Regular Cleaning Procedures. 2. Lubrication of Moving Parts. 3. Inspection and Replacement of Wear Parts. 4. Calibration of Sensors and Controls. 5. Training and Education of Operators. 6. Monitoring Machine Performance. 7. Environmental Considerations. Conclusion: Ensuring Longevity and Efficiency....

YS-SP180J wet pet food nozzle bag packaging machine is specifically designed to handle viscous and semi-liquid pet food products...

YS-80K snacks granular packing machine is suitable for packaging various granular, flake, strip and shaped materials such as candy, melon seeds, peanuts, nuts, beans, potato chips, popc...

YS-80K snacks granular packing machine is suitable for packaging various granular, flake, strip and shaped materials such as candy, melon seeds, peanuts, nuts, beans, potato chips, popc...

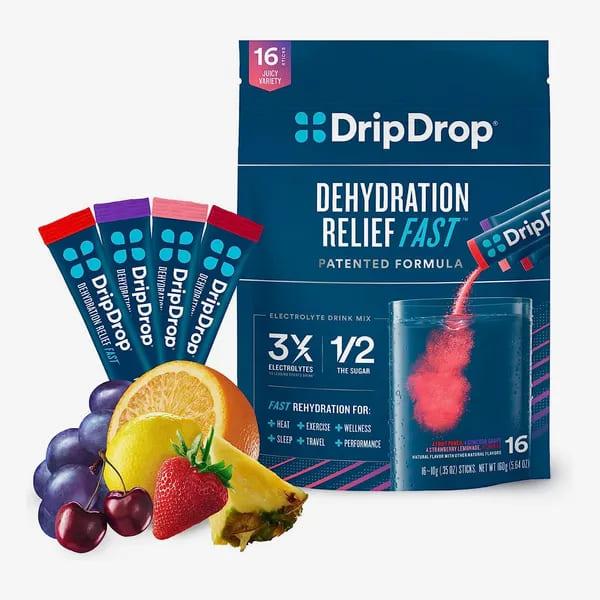

The 65F powder packaging machine provides an efficient and precise packaging solution for electrolyte powder. The machine is equipped with an advanced metering system to ensure that the weight of each pack...

Many of the packaging machines of Yisen are suitable for small particulate materials such as packaging sugar and salt. You can choose packaging according to your needs, and decide based on bag shape and w...

Application: Suitable for packing for all kinds of grain material,sheet material,strip material and abnormity material which such as candy,melon seeds, chips, peanuts, nutlet , pres...

...